- White Papers

- Industry News

- Global Thought Leaders

- Process Water

- Water Reuse

- Produced Water

- Technology Guide

Case Study: Biological wastewater treatment

A food and beverage manufacturer converts its wastewater into energy through biogas production, saving costs and reducing water consumption.

Food and beverage production is a strong water and energy consumer. Water consumption is usually measured using the concept “virtual water,” or the quantity of water needed to produce goods. The virtual water to produce one kilo of beef is about 15,500 liters, and for one kilo of sugar it is about 1,500 liters. On the other side, 1 to 7 liters of water is used in the process of refining about 1 liter of gasoline. It is evident that the food and beverage industry draws huge quantities of water and, with the water footprint becoming increasingly visible in the eyes of consumers, the industry is under pressure to reduce its consumption.

To reduce water consumption, companies should improve their manufacturing processes through a combination of changing behavior, adjusting and/or replacing equipment with water-saving equipment to reduce overall water consumption, and increase internal reuse. Internal reuse of wastewater from manufacturing is a valuable method to meet the current environmental standards and save on energy and operation, as well as maintenance costs.

The promise of biological wastewater treatment

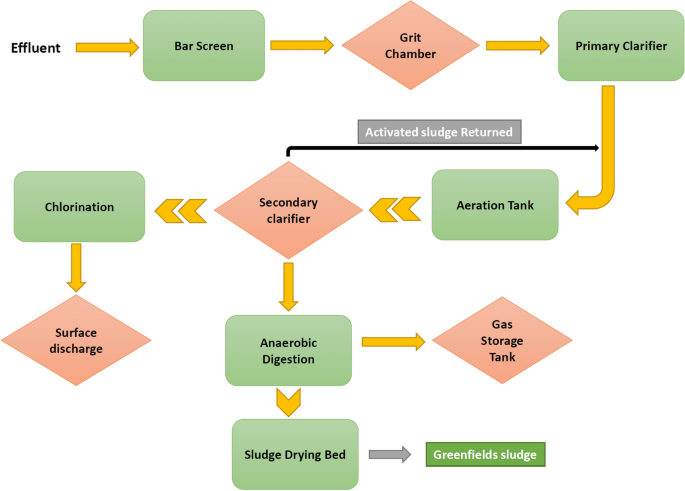

Whether preparing for disposal or reuse, wastewater must be treated with the appropriate technologies. The wastewater from food and beverage manufacturing is especially turbid, high in total suspended solids (TSS), chemical oxygen demands (COD), biological oxygen demand (BOD), fats, oils and grease (FOG), and usually nutrients such as nitrogen (including ammonia) and phosphate. Because of the characteristics of these streams, biological treatment systems are the most suitable to recover the waste streams, treating them for discharge within law limits to reuse them. Biological wastewater treatment, particularly anaerobic digestion, is an excellent choice, and it is becoming popular because the investment in the technology pays for itself through biogas production.

Anaerobic digestion is the simple, natural breakdown of organic matter into methane, carbon dioxide and water by microorganisms. At the end of the process, we have a mixture of methane and carbon dioxide gases (called biogas) and suspension of organic material (digestate), which contains the organic material that has not been degraded, plus the anaerobic bacteria. Biogas can be burned to produce both heat and electricity, or it can be further purified to produce methane, which can be used as vehicle fuel or injected into the gas grid.

Aerobic system, including pumps, tubing and valves

The wastewater challenge for the food and beverage industry

Water consumption is a pressing matter for Italcanditi-Vitalfood, one of the biggest players in Europe for the production of glazed chestnuts, assorted candies, jams, and other ingredients for the food, bakery and dairy industries. Based in the north of Italy, the company is required to dispose of the increasing industrial wastewater effluents from fruit, candies and jam in a cost-effective way. Due to a production growth, Italcanditi-Vitalfood needed to boost its wastewater treatment capabilities. Based on the success of an earlier project, the company chose Fluence Corporation to install and operate a new system for turning wastewater into biogas.

Fluence, an international company with a wide range of solutions for wastewater, waste-to-energy, and food and beverage processing, has developed innovative technologies to transform biological waste – including wastewater – into energy through biological wastewater treatments.

The first challenge Fluence faced in working with Italcanditi-Vitalfood was handling the complicated wastewater streams and treating them for disposal within legal limits or for reuse. One advantage of this application was the COD levels, which made it a good fit for anaerobic digestion. The higher the COD, the higher the energy content of wastes and/or wastewater. It is useful to know that 1 kg of COD, treated by an anaerobic digestion process, produces 0.35 cubic meters of methane, which can be reused in the processing system as combustible.

Anaerobic digestion treatment and process

Italcanditi-Vitalfood chose anaerobic digestion as a way to exploit its wastewater for profit. First, the wastewater entering the system underwent an anaerobic pretreatment through an EFC (external forced circulation) reactor, generating biogas. A cogeneration system then turned the biogas into electrical and thermal energy, which was fed back into the plant, reducing energy costs.

The EFC reactor was an evolution of an up-flow anaerobic sludge blanket (UASB) reactor completely designed and developed by Fluence. An increased flow velocity accomplished by incorporating an effluent recycle permitted partial expansion of the granular sludge bed, improving wastewater-sludge contact, as well as enhancing segregation of small, inactive suspended particle from the sludge bed. The anaerobic reaction was rapid because the large quantity of anaerobic activated sludge permitted abatement of the soluble organic contamination, with very low retention times (6 – 48 h) and with high organic loads (6 – 15 kg COD/m3/day).

The anaerobic digestion produced a pretreated wastewater stream with a specific level of COD and nitrogen. If disposed of without treatment, the nitrogen could penetrate the soil and contaminate groundwater. Therefore, the remaining wastewater was treated by an aerobic stage, supported by biological oxidation and final clarification. The output was water that is clean, reusable and safe for the environment.

External forced circulation (EFC) reactor

Considering space constraints

Another challenge in the design and construction of wastewater treatment plants for food and beverage industry is managing space constraints. These plants are usually located close to conurbations, meaning that land prices are high or land for expansion is not available at all.

In the case of Italcanditi-Vitalfood, located in the industrial area of a small city in the north of Italy, the available space was very limited and the production cycle of 16 hours a day, six days a week could not be affected. Fluence accomplished this by customizing the design and build to the client’s needs, employing an EFC reactor that is, in fact, easy to set up in limited spaces and/or in peculiar locations thanks to its simple design and resistance to disturbances.

Evaluate solutions for biological wastewater treatment

Biological wastewater treatment is the most suitable solution for treating wastewater with high carbon or nitrogen content, as in the food and beverage industry waste streams. And tightening regulations for wastewater treatment worldwide, as well as international commitments to reduce fossil fuels and address water scarcity, have created a growing market for biological wastewater treatment.

Biological wastewater treatment is the most suitable solution for treating wastewater with high carbon or nitrogen content, as in the food and beverage industry waste streams.

Meanwhile, the opportunity to produce renewable energy and cut energy costs make the production of biogas an appealing option for many industries. The advanced maintenance and operation skills necessary to maintain such systems could hinder their adoption, but thanks to Fluence’s skilled engineers and technicians, Italcanditi-Vitalfood was able to realize the benefits of biological wastewater treatment.

Compared to the use of sole aerobic solutions, adding anaerobic treatments also limits the problem of excess secondary sludge. It is usually produced with the use of aerobic systems, and its disposal represents an additional cost for the company. The sludge produced in the EFC reactor is only 5 percent of the destroyed COD – compared to the 40 to 45 percent of the aerobic process.

Final results

Italcanditi-Vitalfood saves about $400,000 each year with Fluence’s anaerobic digester, approximately 35 to 40 percent more compared to the previous treatment plant. After several years of operation, the plant still proves its efficiency with a flow rate of 1,200 m3/d or 50 m3/h, biogas production of 4,800 m3/d, and electricity generation of about 14 MWh/d. Chemical oxygen demand is measured at 12,000 mg/L.

Biological wastewater treatment tackles most wastewater challenges in the food and beverage industry. Difficult wastewater streams are converted into renewable energy, which can be fed back into the manufacturing process in the form of heat and electricity. The combination of aerobic and anaerobic solutions is a recipe to maximize energy production and minimize energy costs for the food and beverage industry. This solution is also relevant for other industries where high organic soluble compounds are found in effluents, such as paper mills.

Fabio Poletto is vice president of sales and marketing, Italy, for Fluence Corporation . With a background in water treatment technologies for the food and beverage industry, Poletto has carried out innovative research on nitrification and denitrification treatments, anaerobic digestion and chemical-physical wastewater treatments. He has a master’s degree in chemistry from the University of Padua, specializing in innovative chemical technologies. He can be reached at [email protected] .

Continue Reading

Case study: First Ultra PX for wastewater treatment yields high-performance savings

Mobile nanobubble service provides seasonal and on-demand water treatment in North America

Sponsored recommendations.

NFPA 70B a Step-by-Step Guide to Compliance

How digital twins drive more environmentally conscious medium- and low-voltage equipment design

MV equipment sustainability depends on environmentally conscious design values

Social Distancing from your electrical equipment?

Latest in wastewater.

Common mistakes to avoid in industrial wastewater management

Debunking common myths about industrial wastewater

‘Head’ and ‘pressure’ in pumps

The role of reverse osmosis in wastewater treatment

Unlocking the power of corporate sustainability and active energy management

The Digital Solution: How Digitization is Driving Global Water Sustainability Goals

Team up with GMF to deliver climate adaptation training. Learn more

Wastewater case studies: Solutions and strategies

Best practices for meeting canadian municipal wastewater regulations.

Are you looking for technical information and examples of best practices to help you with your municipality's wastewater treatment initiative? We have developed case studies to help Canadian cities and towns of all sizes meet the wastewater regulations introduced by the federal government. The case studies provide valuable information that you can apply to your own wastewater treatment plant projects and upgrades. They include technical information, project details, tips on best practices and the significant benefits gained by community members. Read the case studies to learn the steps you can take to:

- Upgrade, retrofit or replace your wastewater treatment system.

- Increase capacity and extend the service life of your wastewater treatment plant.

- Improve wastewater quality, reduce odour levels and eliminate chemical residues.

- Learn about alternative ways to minimize energy use.

Each study also includes contact information so you can connect with people who have firsthand experience overcoming specific challenges and obstacles in these initiatives. Connect with them to ask for advice on projects in your municipality.

Read the case studies in our series

- Prince Edward County's new facility uses full cost recovery approach

- Amherstburg saves land, consolidating three sewage treatment plants into one

- Energy-efficient upgrades reduce operating costs at Wetaskiwin wastewater treatment plant

- New Chatham-Kent wastewater treatment facility reduces E. coli

- How Waterloo facility upgrades improve water quality and energy efficiency

- Brockville adds secondary and UV treatment to its wastewater treatment plant

- Greater water treatment capacity supports community growth in St. Louis

- St. Andrews revitalizes community after wastewater plant upgrades

- Upgrades allow Argyle to expand sewer system, reduce septic tank use

- New disinfection techniques improve public health in Kapuskasing

- How Barrie's new wastewater plant improves capacity and efficiency

- Facility upgrades help Cranbrook enhance agricultural production

Want to explore all GMF-funded projects? Check out the Projects Database for a complete overview of funded projects and get inspired by municipalities of all sizes, across Canada.

Visit the projects database

Related Resources

Webinar recording: How to get a project started, tips for small francophone communities

If you’re a small francophone municipality looking to develop sustainability projects and access funding, watch this webinar to learn how others overcame common challenges.

Webinar recording: Become a Climate Champion for Your Community

Watch this webinar recording to see how community climate champions face unique challenges in their role as they drive forward new ideas, mobilize partners, build relationships, and make tough decisions.

Webinar Recording: Sustainable municipal water management

Watch the webinar recording to discover current trends and research on the importance of sustainable municipal water management.

Video: Yorkton meets their feasibility study goals by valuing community involvement

Glenda Holmes, Water Works Manager, explains how a feasibility study helped the City of Yorkton ramp up the environmental benefits of its new water treatment plant by treating the wastewater it produced.

Webinar recording: Take your project from study to capital

Watch this webinar recording and discover how others have successfully converted studies into a capital project that provides social, economic and environmental benefits.

Webinar recording: The 5 keys to a green municipal project business case

Watch this webinar recording and discover the five critical focus areas you need to address to get your project started, from financing and partnerships to integrating a triple-bottom-line approach.

Webinar recordings: Best practices in municipal sustainability

How are cities and communities of all sizes tackling their environmental challenges? Find out from our five-part webinar series on innovations and opportunities in municipal energy, waste, water, transportation and land use initiatives.

Report: Water management trends in Canadian municipalities

A snapshot of existing and emerging water management trends, best practices and opportunities for innovation.

Guide: 2018 Sustainable Communities Awards project guide: Water

Learn how to implement the best practices and strategies used by Okotoks, AB, our 2018 Sustainable Communities Awards water winner.

Webinar recording: How to prepare a GMF capital project application

Need advice for preparing your GMF capital project funding application? Watch our webinar recording to hear tips from our staff and find out what reviewers are looking for.

Guide: Best practices for scoping a wastewater upgrade project

Get your wastewater project off to a successful start with these best practices in defining project scope and engaging stakeholders. Part one in a three-part article series.

Guide: Lessons in planning and designing a wastewater plant upgrade

Learn how to avoid one of the most common mistakes in wastewater plant upgrade projects: insufficient planning and analysis. Part two in a three-part article series.

Guide: Tips for the building phase of a wastewater plant upgrade

Discover four practices that will help make the procurement, construction and start-up phase of your project a success. Part three in a three-part article series.

Six sustainability ideas that have gone mainstream in Canada: Article series

In a series of six articles, we explore inspiring projects and sustainability solutions being implemented in cities and towns of all sizes across Canada.

Tool: Checklist for a successful wastewater treatment plant upgrade

Follow this checklist based on best practices to help ensure success and address key issues during each phase of your project.

Article series: Tips for a successful wastewater treatment plant upgrade

Implement a successful wastewater treatment plant upgrade with help from this series of three articles packed with best practices from GMF-funded projects. Read the articles.

Webinar recording: Wastewater best practices, strategies and solutions

Watch the webinar recordings from our three-part, online workshop series on wastewater best practices, strategies and solutions for Canadian municipalities.

Guide: Sustainable Neighbourhood Development

This guide, Sustainable Neighbourhood Development: Practical Solutions to Common Challenges, is designed to help you re-imagine your municipality's approach to planning, development and regulation.

Webinar recording: Optimizing your wastewater treatment plant

Join our webinar to learn proven practices to help you identify ways to optimize your existing wastewater treatment resources. Speakers from the Ontario Ministry of the Environment and Climate Change and the Grand River Conservation Authority will share lessons learned that you can apply in your municipality.

Webinar recording: Managing stormwater through low impact development

Learn how to use green stormwater infrastructure, or low impact development, as an affordable alternative to grey stormwater infrastructure in your community.

Related Funding

Study: net-zero transformation.

Available funding: Assess new approaches and solutions to bring your community closer to net-zero.

Pilot: Net-Zero Transformation

Available funding: Evaluate innovative GHG reduction solutions in real-world conditions.

Capital project: Net-Zero Transformation

Available funding: Deploy a full scale best-in-class GHG reduction solution.

Plan: Net-Zero Transformation

Available funding: Conduct integrated planning exercises to support the municipal transition to net zero.

Related Projects

Case study: Two natural solutions to manage stormwater runoff

Case study: understanding climate change impacts key to prioritizing drainage infrastructure projects in vernon, bc, upcoming events, webinar: find support for your community building retrofits, webinar: inclusive engagement for net zero acceleration projects.

REVIEW article

Comprehensive assessment of microalgal-based treatment processes for dairy wastewater.

- 1 Department of Chemical Engineering, Indian Institute of Technology Guwahati, Guwahati, India

- 2 Division of Biotechnology, Karunya Institute of Technology and Sciences, Coimbatore, India

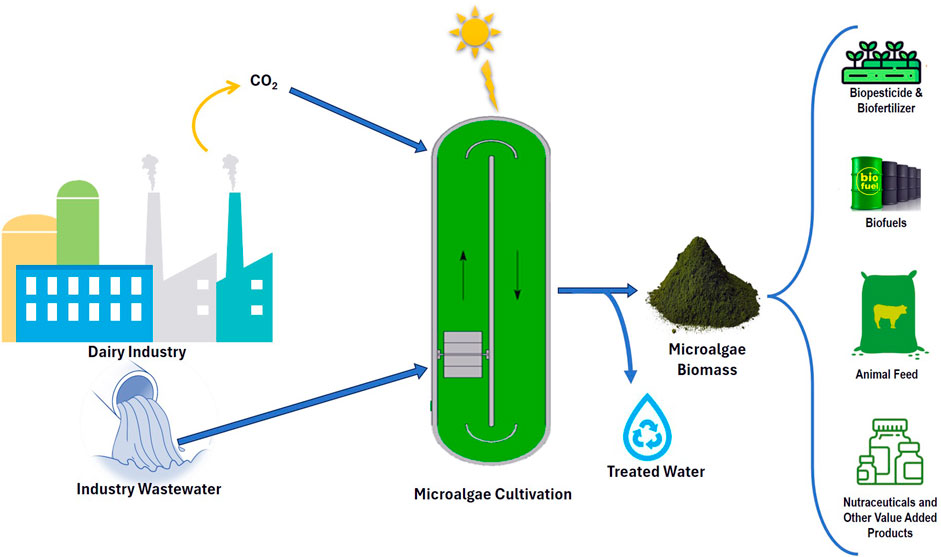

The dairy industry is becoming one of the biggest sectors within the global food industry, and these industries use almost 34% of the water. The amount of water used is governed by the production process and the technologies employed in the plants. Consequently, the dairy industries generate almost 0.2–10 L of wastewater per liter of processed milk, which must be treated before being discharged into water bodies. The cultivation of microalgae in a mixotrophic regime using dairy wastewater enhances biomass growth, productivity, and the accumulation of value-added product. The generated biomass can be converted into biofuels, thus limiting the dependence on petroleum-based crude oil. To fulfill the algal biorefinery model, it is important to utilize every waste stream in a cascade loop. Additionally, the harvested water generated from algal biomass production can be recycled for further microalgal growth. Economic and sustainable wastewater management, along with proper reclamation of nutrients from dairy wastewater, is a promising approach to mitigate the problem of water scarcity. A bibliometric study revealing limited work on dairy wastewater treatment using microalgae for biofuel production. And, limited work is reported on the pretreatment of dairy wastewater via physicochemical methods before microalgal-based treatment. There are still significant gaps remains in large-scale cultivation processes. It is also crucial to discover robust strains that are highly compatible with the specific concentration of contaminants, as this will lead to increased yields and productivity for the targeted bio-product. Finally, research on reutilization of culture media in photobioreactor is necessary to augument the productivity of the entire process. Therefore, the incorporation of the microalgal biorefinery with the wastewater treatment concept has great potential for promoting ecological sustainability.

1 Introduction

The exhaustion of fossil fuels in transportation and industrial sectors has resulted in the depletion of already available natural resources together with the emission of notable greenhouse gases. Nowadays, studies are focused on finding renewable energy feedstock to overcome the coming energy crisis and to lower down the footprint of global warming ( Chandra et al., 2021 ). Microalgae are gaining global recognition for their potential uses in several industries, including bioenergy, medicines, aquaculture, food, agriculture, and bioplastics ( Arora et al., 2021 ; Agarwalla et al., 2023 ; Ramírez Mérida and Rodríguez Padrón, 2023 ; Agarwalla and Mohanty, 2024 ). Furthermore, there is research going on the potential of microalgae to remove calcitrant and harmful compounds, with the aim of industrial wastewater treatment. Industrial-scale growth of microalgae necessitates the use of large quantities of water and nutrients. Utilizing nonpotable water for growing microalgae may reduce the need for freshwater. The lower biomass productivity and elevated expense of growth media are the challenges linked with the production of microalgal biomass for various applications. The utilization of industrial effluent for cultivating microalgae has become a substitute to decrease the costs of the process and to produce biomass. The dairy industries are operating worldwide, but the cost of manufacturing processes differs from area to area. India, with a large population dependent on livestock and agriculture for their income, has emerged as a significant hub for the dairy industry. Almost 200–10,000 mL of wastewater is produced/L of processed milk and it must be treated before discharging to water bodies ( Chandra et al., 2021 ). The effluent generated from the dairy industry has a high concentration of organic compounds and is not considered safe due to its high chemical oxygen demand (COD) and biochemical oxygen demand (BOD). Nevertheless, this dairy wastewater (DW) could be an excellent source of nutrients for microalgae which is rich in sugars, amino acids, ammonium, and phosphates sources ( Vieira Costa et al., 2021 ). Cultivating the microalgae in dairy effluents has numerous benefits, including the ability to grow using available nutrients in the wastewater without adding additional nutrients ( Singh et al., 2023 ; Ravi Kiran et al., 2024 ). This process also reduces the COD and BOD of the effluent, providing a cost-effective method for treating dairy waste. Additionally, it offers the potential to extract valuable products like lipids, proteins, and carbohydrates for various applications ( Chandra et al., 2021 ). This review investigation aims to present recent studies in the area of microalgal-based dairy wastewater treatment. This is the first study to present a scientometric analysis of dairy wastewater treatment using microalgae. Also, a comprehensive assessment was conducted on previous studies in this review literature. In this literature, the importance of cultivation of microalgae in dairy effluent was highlighted as a source of growth media which can reduce the cost of the overall biomass generation process. Additionally, this review presents the characteristics of the different dairy wastewater and the efficiency of microalgae in the remediation of wastewater.

1.1 Background and significance of dairy wastewater

Due to the increased public awareness regarding nutrition and health over the past 45 years, the dairy industry has developed into a highly organized sector. There are over 101,000 number of milk co-operatives operating throughout the nation to provide milk processing, distribution, and large-scale production through a large number of dairies. With a milk production of 155.2 million tonnes in 2016–17, India has surpassed all other countries to take the lead globally. The cooperative/government and private sectors collectively operate over a thousand dairies that produce an estimated 100 million liters of milk daily ( Singh et al., 2023 ). Within the global food industry, the dairy market is one of the biggest sectors. The dairy farmers in the food industry use 34% of the water. The amount of water used is governed by the production process and the technologies used in the plant. The application of sufficient hygienic levels in manufacturing and the urge to decrease the usage of water and enhance the efficacy of the treatment of wastewater are challenges that demand different approaches. The dairy sector consumes between 1,000 and 10,000 L of water for processing 1,000 L of milk. Based on data from the FAO (Food and Agriculture Organisation), global milk production has seen a significant growth of over 59% in the past 30 years. Specifically, it has risen from 530 million tonnes in 1988 to 843 million tonnes in 2018. With a quarter of the world’s milk produced, India leads the world’s milk producers, followed by the US, China, Pakistan, and Brazil. DW refers to the effluent that is produced by dairy organizations ( Aziz and Ali, 2017 ). It has a whitish shade, accompanied by an unpleasant odor and a cloudy appearance ( Kolev Slavov, 2017 ). Dairy wastewater includes significant amounts of milk solids, fats, nutrients, lactose, detergents, and sterilizing agents which correspond to elevated levels of biological oxygen demand ranging from 40 to 48,000 mg L -1 , chemical oxygen demand ranging from 80 to 95,000 mg L -1 , and pH values that vary between 4 and 11. The difference in pH levels is attributed to the presence of different detergents in the water for cleaning ( Vieira Costa et al., 2021 ). The inappropriate release of DW into water bodies without adequate treatment not only leads to environmental contamination but also impacts nearby groundwater and reservoirs of water, thus adversely affecting human health ( Garcha et al., 2016 ). This phenomenon arises from the rapid degradation of DW components. As a result, the concentrations of dissolved oxygen in the water bodies are depleted that receive these effluents. Consequently, these streams become breeding grounds for disease-carrying insects ( Vieira Costa et al., 2021 ). Also, these industries generate effluents that include high concentrations of oils and greases, which have detrimental effects on wastewater treatment systems. The oil and grease content of raw dairy wastewater collected from an unorganized dairy industry of Patiala, Ludhiana, Shri Muktsar Sahib, and Bathinda (Punjab, India) was found to be within the range of 218–700 mg L -1 ( Garcha et al., 2016 ). These effluents often lead to foul odors and obstructions in pipes. The wastewater also includes significant levels of nutrients, which may support the growth of several unidentified bacteria. Therefore, to accomplish effective biological remediation, it is crucial to ascertain the bacterial composition in the wastewater ( Vieira Costa et al., 2021 ). Dairy wastewater often includes a significant abundance of heterotrophic bacteria, including species such as Pseudomonas ( Alalam et al., 2021 ), Bacillus cereus ( Garcha et al., 2016 ), Enterobacter ( Alalam et al., 2021 ), Streptococcus ( Alalam et al., 2021 ), and Escherichia coli ( Boutilier et al., 2009 ). Microalgae can efficaciously utilize the nutrients available in DW and simultaneously produce valuable products. The amalgamation of algae cultivation with dairy wastewater treatment yields significant advantages, including the conservation of water resources, cost-effective bioremediation of the wastewater, generation of biomass suitable for bioenergy and animal feed, and the emergence of possibilities for the development of other high-value products ( Singh et al., 2023 ).

1.2 Importance of microalgal-based treatment processes

Microalgae are photosynthetic organisms, may exist as single-celled or multi-celled organisms, and survive in both freshwater and saltwater ecosystems. These can effectively use carbon dioxide, light, and water to produce a range of valuable bioactive chemicals, including carbohydrates, proteins, and lipids. Various studies utilize microalgal biomass for other commercially valuable purposes. These include extracting pigments and vitamins for animal feed ( Vieira Costa et al., 2021 ), and producing antioxidant, antitumor, anti-inflammatory, and antimicrobial compounds ( Divya Kuravi and Venkata Mohan, 2021 ; Kiran and Venkata Mohan, 2022 ), generating biofuels ( Singh et al., 2023 ; Ravi Kiran et al., 2024 ). Microalgae have been extensively employed for wastewater treatment. The two genera being the most extensively cultivated and studied worldwide in recent times were Chlorella and Spirulina ( Vieira Costa et al., 2021 ). The process of phycoremediation involves first selecting the species and mode of cultivation, followed by pretreatment for product extraction and purification. However, the cost of cell productivity, contamination, and low yield are challenges that must be overcome to enable the scalability of this process ( Vieira Costa et al., 2021 ). The primary physicochemical parameters that influence cell productivity are light intensity, nutrient, pH value, temperature, CO 2 amount, salinity, and aeration. The light intensity and concentrations of nutrients are limiting variables for the growth of microalgal cells during the cultivation period. The intensity and length of light throughout the photoperiod control the photosynthesis energy supply, whereas the nutrient content directly affects the cellular metabolism and structure. Carbon, phosphate, and nitrogen are regarded as the most vital components of the metabolic pathway for photosynthesis. The metal ions present in the wastewater help in osmoregulation and the molecular configuration of photosynthetic complexes. The most critical parameter to consider when cultivating the microalgae is the pH. Maintaining the pH within the optimal range for microalgal cultivation promotes biomass production, which is also an important factor in terms of the solubility of nutrients ( Vieira Costa et al., 2021 ). These conditions account for 30% of production costs in large-scale microalgae production. The bioreactor design and harvesting method are also a crucial factors in influencing the efficiency of large-scale biomass generation and overall production cost ( Agarwalla et al., 2023 ; Agarwalla and Mohanty, 2024 ).

1.3 Importance of clean water generation and high-value product extraction

Post-harvesting represents an additional significant obstacle in the generation of microalgae biomass. Typically, biomass concentrations of microalgae cultures range from 0.5 to 18 g/L. As a result, a substantial quantity of water must be extracted to separate algal biomass ( Kumar et al., 2019a ). Two steps comprise the harvesting procedure: sedimentation/flocculation and dewatering. Microalgal cells have a very lower size range and, thus are impracticable to extract via conventional sedimentation. Centrifugation is the commonly used technology but it is a costly and energy-intensive process. Hence, there is a requirement for a secondary cost-effective process with the ability to harvest large-capacity culture. Flocculation is a process that can overcome such drawbacks and it involves the interaction between cell surface charges and flocculant charges. This process results in the generation of agglomerates in the medium which can be settled under the effect of gravity and can yield a concentrated algal slurry that contains at least 25% dry matter. For microalgae harvesting, numerous flocculation techniques have been documented; among these, chemical flocculation, bio-flocculation, and auto-flocculation have received the most research attention ( Kumar et al., 2019a ; Arora et al., 2021 ; Agarwalla and Mohanty, 2024 ). The economic and sustainable wastewater management along with proper recovery of nutrients from wastewater is a favorable outlook to mitigate the problem of water scarcity ( Yadav et al., 2022 ).

Microalgae are increasingly recognized as a highly promising and sustainable long-term renewable resource. Algae with a high lipid content and rapid growth rate are chosen for a variety of applications across industries, including the production of biofuel, exopolysaccharides, biopolymers, and biofertilizers ( Arora et al., 2021 ; Ramírez Mérida and Rodríguez Padrón, 2023 ). The increase in plastic usage in daily life leads to environmental pollution and these plastics are recalcitrant for degradation using microbes. Therefore, bioplastic can be an alternative to conventional plastics. These bioplastics raw materials can be obtained from biological sources like bacteria, microalgae, yeast, and transgenic plants. The biologically derived plastics are polyhydroxyalkanoates (PHA), polylactic acid, starch, and carbohydrates. These polymers can be extracted from biomass; extracellularly and intracellularly produced by microorganisms; and synthesized by bio-derivatives ( Arora et al., 2021 ). Many microalgal strains are cultivated for polyhydroxyalkanoates production in different wastewater and stress conditions ( Laycock et al., 2014 ; Wicker et al., 2022 ; Kusmayadi et al., 2023 ). Laycock et al. reported the production of 10 wt% of polyhydroxyalkanoates from Spirulina platensis in the presence of acetate and CO 2 ( Laycock et al., 2014 ). In another study, a photosynthetic consortium was cultivated in raw aquaculture effluent for polyhydroxybutyrate (PHB) production. The most significant amounts of PHB accumulation were seen under the high-intensity full-spectrum light treatment, which is correlated to biomass production, carbon utilization, and nutrient removal ( Wicker et al., 2022 ). PHA also has applications in the medical sector such as scaffolds, tissue engineering, and surgical sutures. Additionally, microalgae can be used as biofertilizers when cultivated on wastewater ( Arora et al., 2021 ). An experiment conducted by Das et al. (2019a) reported a yield of 650 mg L –1 of Chlorella sp. microalgae cultivated in municipal waste as a biofertilizer. Furthermore, the accumulated lipids in microalgae can be used as feedstock for biodiesel production ( Hemalatha et al., 2019 ) while the whole biomass can be converted into bio-oil via thermochemical methods ( Ravi Kiran et al., 2024 ). Also, the microalgae can undergo pretreatment for extraction of carbohydrates for bioethanol and biohydrogen production ( Chokshi et al., 2016 ; Bhatia et al., 2021 ). In this line, the studies should be focussed on the integration of dairy wastewater bioremediation using microalgae, recycling of water, and biomass processing into value-added products or fuel.

2 Characteristics of dairy wastewater

2.1 composition and properties of raw wastewater.

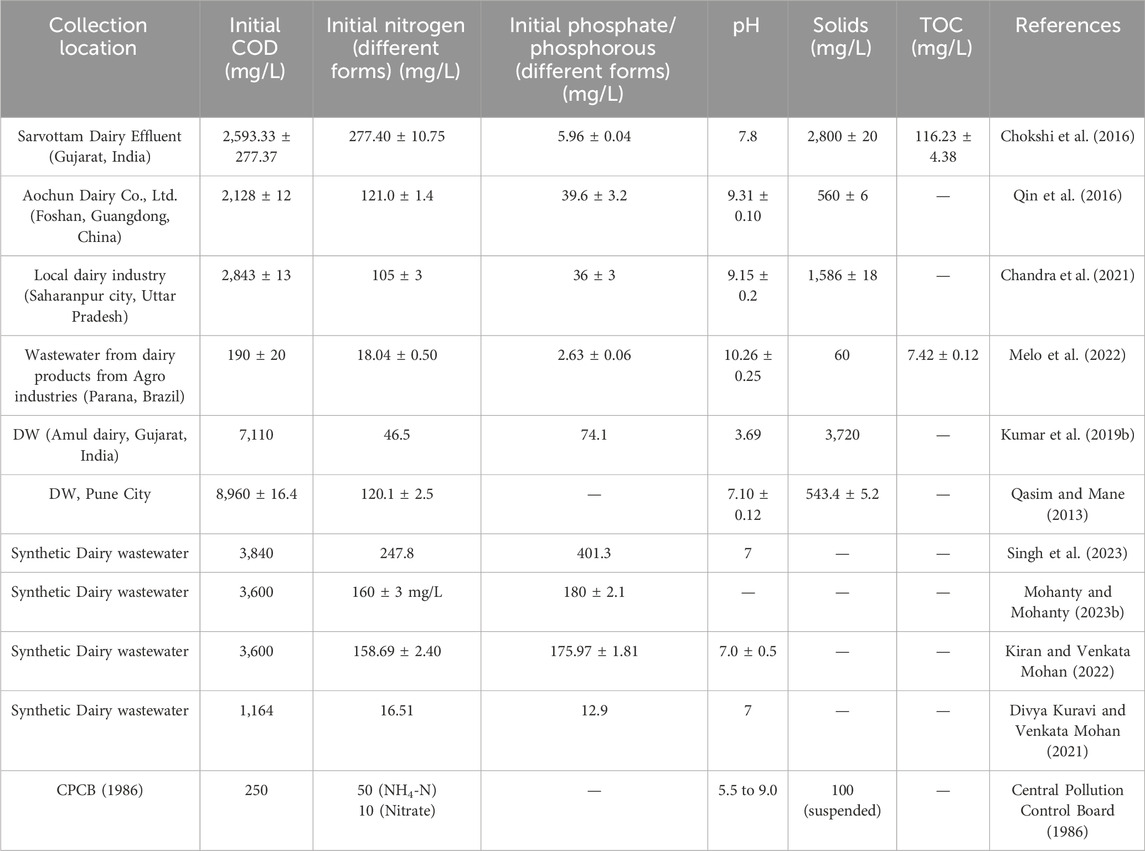

Nowadays, the dairy industry wastewater is surveyed as one of the most polluted effluents in terms of BOD, COD, and total suspended solids (TSS). However, the volume of wastewater and pollution load is dependent on the type of products produced and the production process. The sterilized packaging unit of the Saras dairy factory processes a total of 1,00,000 L of milk/day, whereas the facility’s processing capacity is 5,00,000 L per day. Brar et al. reported that wastewater generated from dairy wastewater from the Saras dairy plant, Jaipur has a COD of 1,280 ± 226.47 mg L −1 and BOD of 245.95 ± 8.48 mg L −1 . The total phosphate and nitrogen content of the dairy wastewater also has significant values of 19,583 ± 424 mg L −1 and 363.97 ± 23.93 mg L −1 , respectively ( Brar et al., 2019 ). Comparatively, the dairy wastewater at Jelgava, Latvia has a COD of 1,680 ± 20 mg L −1 and BOD of 1,196 ± 50 mg L −1 , which is higher than the permissible limits. The wastewater contains nitrogen and phosphate of 115 ± 30 mg L −1 and 22 ± 05 mg L −1 . Also, the wastewater reported the presence of lipids which was confirmed by Nuclear Magnetic Resonance (NMR) spectroscopy ( Ekka et al., 2022 ). Qasim and Mane characterized the dairy wastewater of Pune City, Maharashtra, as having a COD of 8,960 ± 716.4 mg L −1 and BOD of 442 ± 3.1 mg L −1 ( Qasim and Mane, 2013 ). A study reported that wastewater generated from yogurt and buttermilk dairy wastewater has less pollution load in terms of COD and BOD. A dairy factory in Erbil City generates 40–50 tons of yogurt and buttermilk every day. The COD value ranges from 0.986 to 1.132 g L −1 and BOD ranges from 0.6 to 0.8 g L −1 ( Aziz and Ali, 2017 ). When the DW is released into the lakes and rivers without any treatment leads to eutrophication. This increases the growth of microorganisms that may deplete the dissolved oxygen in the water bodies. This makes the dairy sector one of the most notable contributors to the pollution of water bodies. pH is an important parameter in considering the quality of wastewater because microbial growth will depend on the pH of the wastewater. White wastewater produced after the cleaning of pasteurizers from both two Canadian dairy plants has an alkaline pH ranging from 8.23 to 12.45. However, the total solid from plant A (0.50 ± 0.04 g/L) was comparatively less than from plant B (3.12 ± 0.24 g/L), which signifies less dilution of later. Also, the alkaline and acidic wastewater were collected after second and fourth steps of the cleaning-in-place protocol and characterized for their chemical properties. The acidic wastewater generated from both plants A and B has very acidic pH (1.82 ± 0.06-plant A and 1.17 ± 0.01-plant B) with comparative electrical conductivity (5.35 ± 0.10 μS/cm -plant A and 14.25 ± 0.13 μS/cm -plant B). The comparative conductivity was observed due to significant calcium ions (177.04 ± 0.43 mg/L) reported from plant B acidic wastewater ( Alalam et al., 2021 ). The pH of Yoruksut dairy wastewater has a slight acid-to-neutral range (6.75–7.71) while the total solid was less (1,200 mg/L) in March compared to May month (3,900 mg/L), exceeding the EPA limit ( Aziz and Ali, 2017 ). Sawalha et al. characterized the dairy industry wastewater in Palestine and conducted an adsorption study using biowaste. Three samples were collected after pasteurization, cheese making, and washing process (soda washing and acid washing). The wastewater from different places was massively concentrated in terms of organics, chloride ions, pH, and TSS. However, the organics and TSS of cheese production wastewater were higher than those from the yogurt production process ( Sawalha et al., 2022 ). TSS are crucial polluting indicator that is used for evaluating DW pollution and to measure the effectiveness of the wastewater treatment plant. The suspended matter in wastewater comes from viscous milk and small fragments of curd or flavorings ( Garcha et al., 2016 ). The higher value of TSS and COD in cheese wastewater might be a result of whey protein, lactose, and fats ( Sawalha et al., 2022 ). Whey wastewater has a high level of organic matter and nutrients, which can be utilized by microorganisms for their growth and metabolism. In another investigation, de Andrade et al. collected and analyzed the curd cheese whey for microalgal bioremediation. The whey has COD of 52,886 ± 269.25 mg L −1 with total nitrogen and phosphate of 1.56 ± 0.035 g L −1 and 0.66 ± 0.012 g L −1 , respectively ( de Andrade et al., 2023 ). In a study conducted by Bharadwaj et al., 52 microbes which include both bacteria and fungi have been identified and subjected to a screening process to determine their efficiency in degrading dairy wastewater. The genera Serratia , Stenotrophomonas , Brachybacterium , and Cunninghamella were reported for their activity in degrading dairy wastewater. The COD level of wastewater was reduced to 58%–72% using these three native genera ( Bhardwaj et al., 2018 ). Overall, in both developed and developing nations, compliance with stringent environmental regulations has become obligatory for the discharge of effluents beyond the allowable limit. The initial physicochemical characteristics of different dairy wastewater collected is given in Table 1 .

Table 1 . Initial physico-chemical characteristics of different collected and synthetic dairy wastewater.

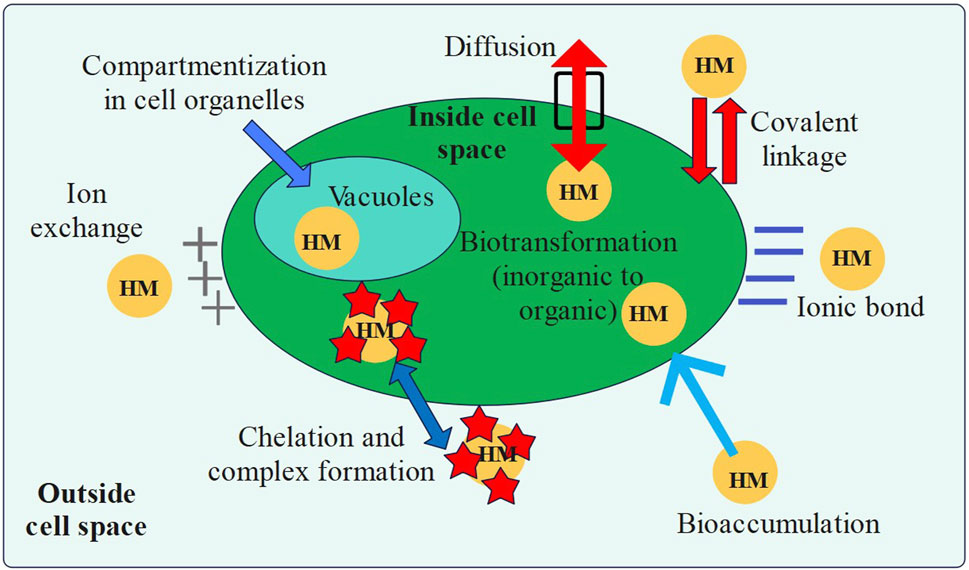

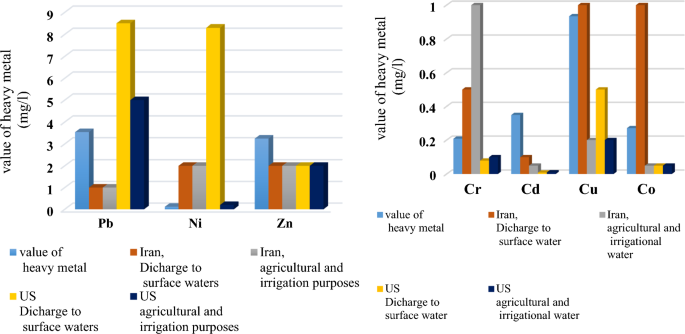

2.2 Evaluation of metals and organic matter present in the wastewater

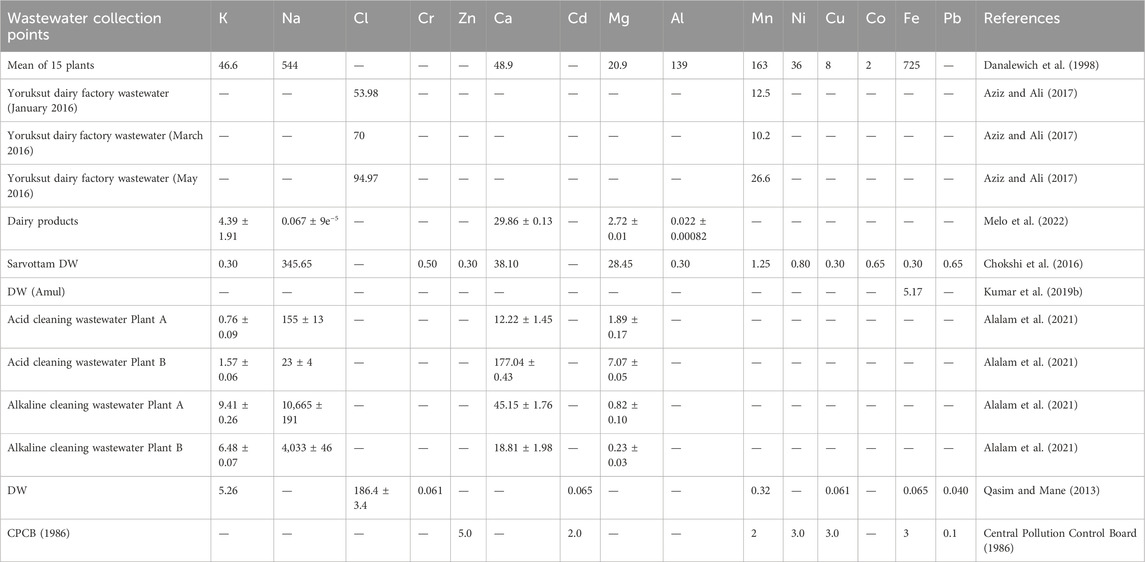

The presence of organic matter like urea, carbohydrates, and fats also affects the quality of the wastewater. Various fatty acids were analyzed in wastewater from the dairy industry situated at Jelgava, Latvia. The wastewater comprises 65% hexadecanoic acid followed by 21% octadecanoic acid. Tetradecanoic acid was also present in wastewater in major amounts but oleic acid, linolenic acid, lauric acid, and linoleic acids were present in smaller concentrations. It was found that milk fatty acids majorly consist of saturated fatty acids. The presence of fatty acids in dairy wastewater offers a viable and cheap option for biodiesel production ( Ekka et al., 2022 ). The quality and treatment efficiency of dairy wastewater also depend on the types of organic matter present in them because these compounds can attach to particulates and can cause abrasion, deposition, and clogging of membranes and filters during operations. The examination of trace organic chemicals found in the effluent of a dairy plant revealed the presence of common milk degradation products as well as compounds that may be linked to their synthetic or agricultural origins. The compounds that were found to be highest in the effluent are 1-Methyl-5-oxo-L-proline methyl ester ( Verheyen et al., 2011 ). Zinc (Zn), cobalt (Co), copper (Cu), chromium (Cr), iron (Fe), and lead (Pb) are among the prevalent heavy metal pollutants detected in DW, and they are significantly considered as most critical global environmental problems ( Table 2 ). Metals that are present in water bodies can persist for a prolonged amount of time or undergo biological transformations. Eventually, they accumulate throughout the food chain, presenting a significant threat to the ecology if not adequately removed. Removing heavy metals from wastewater is challenging due to their resistance to chemical or biological treatment. The chloride, iron, and fluoride concentrations of 199, 5.17, and 4.833 mg L −1 were addressed by Kumar et al. in raw dairy wastewater collected from Amul Dairy, Gujarat, India ( Kumar et al., 2019b ). Also, the dairy eluent collected from Pune City has a chloride level of 186.4 ± 3.4 mg L −1 ( Qasim and Mane, 2013 ), which is lower than EPA regulations. The DW obtained from Sarvottam Dairy effluent contained a high amount of sodium (345.65 mg/L). While little amount of nickel, copper, cobalt, iron, and chromium was observed in DW ( Chokshi et al., 2016 ). The elevated levels of sodium and chloride are attributed to the extensive use of alkaline cleaning agents in dairy facilities. Aluminum can come from aluminum sulfate which is frequently employed in water treatment facilities for the purpose of clarifying the water ( Qasim and Mane, 2013 ). Trace elements such as copper and zinc, as well as other heavy metals including cadmium, arsenic, chromium, and mercury, may be found in dairy wastewater. These elements enter the wastewater via therapeutic substances and organic molecules from pesticides ( Qasim and Mane, 2013 ).

Table 2 . Comparison of metals present in the different dairy industry generated wastewater. Every metals is reported in mg/L.

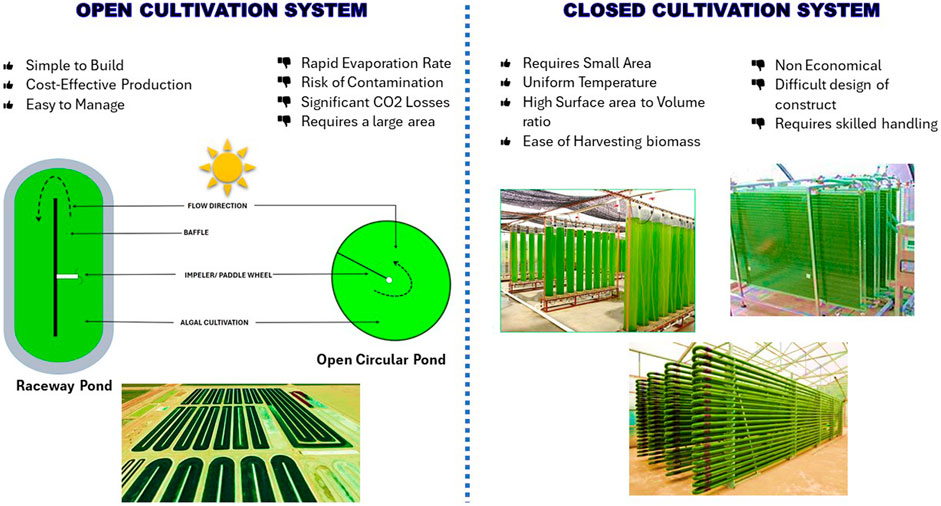

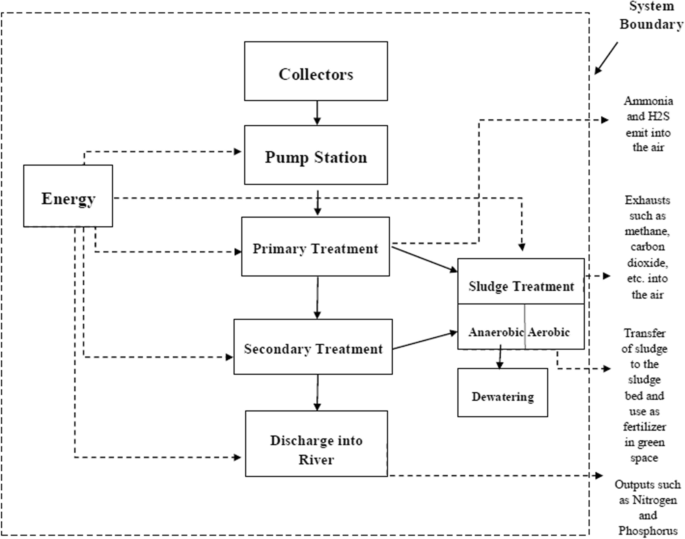

3 Dairy wastewater treatment technologies

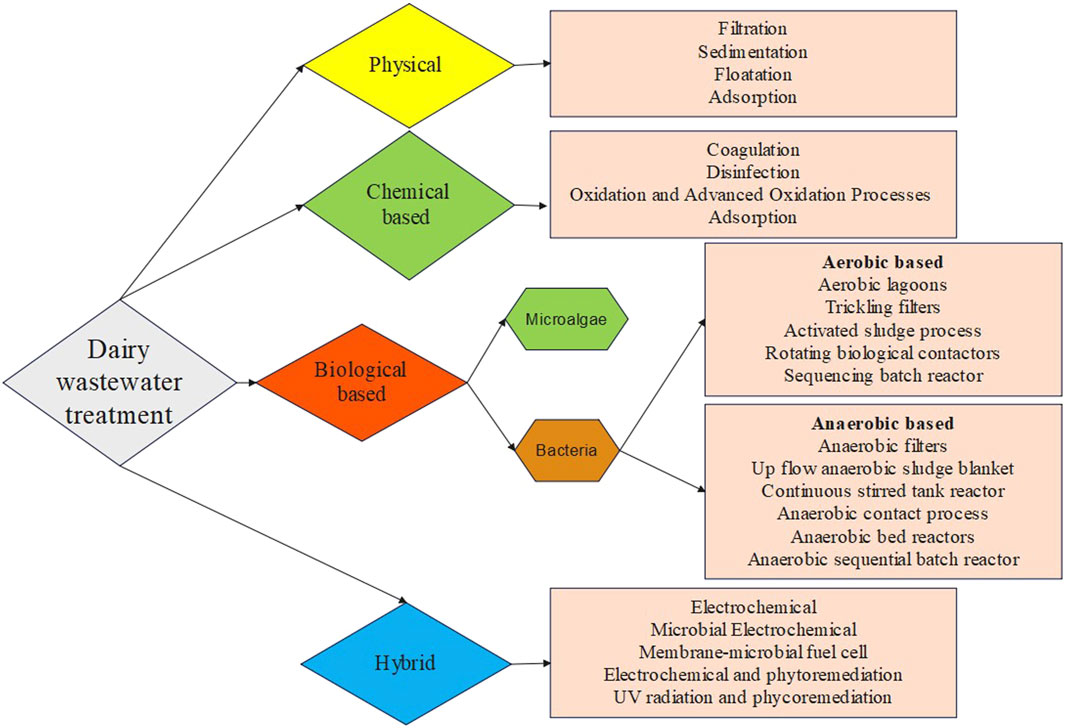

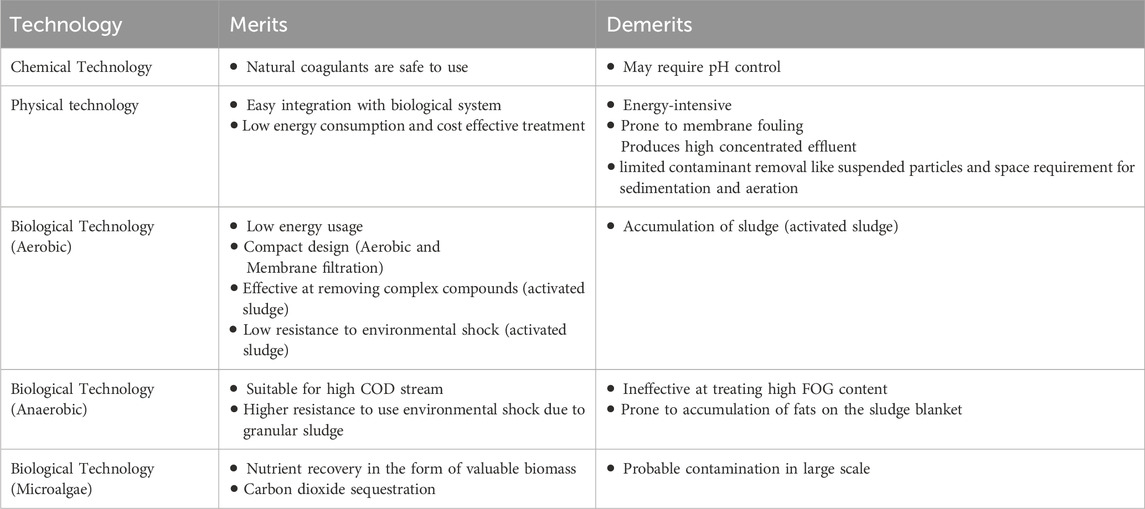

Dairy wastewater has the potential to serve as a nutrient source for the production of biomass and recovery of value-added products. The complex characteristics of dairy wastewater make it a challenging category of industrial wastewater, namely, because of the high-fat content and high levels of COD. Dairy effluent is treated using four major different approaches: coagulation, membrane technology, biological methods, and hybrid methods in previous studies ( Table 3 ; Figure 1 ). Every technology has its advantages and disadvantages in treating dairy wastewater ( Table 4 ). The selection of technology and reactor required for the design of an effluent treatment plant is determined by the availability of land, infrastructure, and the efficiency of focused treatment ( Krishna B et al., 2022 ).

Table 3 . Treatment technologies reported for Dairy Wastewater.

Figure 1 . Various dairy wastewater treatment technologies.

Table 4 . Comparative table on advantages and disadvantages of various treatment technologies.

3.1 Physical treatment technology

As dairy industrial wastewater contains high amounts of dissolved organic matter, membrane technology offers many advantages, including a high degree of removing the dissolved, colloidal, and particulate matter; selectivity in the removal of contaminants based on size; and the possibility for extremely compact treatment facilities ( Turan, 2004 ). The dairy industrial wastewater is initially screened to remove the large debris that can clog the further treatment pipelines. The delay in the screening step may increase the COD of wastewater due to solid solubilization ( Zainab et al., 2019 ). Many studies have been reported earlier for the treatment of dairy wastewater using reverse osmosis (RO) ( Turan, 2004 ), nanofiltration (NF) ( Turan, 2004 ; Luo et al., 2012 ), and ultrafiltration (UF) ( Gong et al., 2012 ; Tayawi et al., 2023 ). RO membrane was used for the treatment of high-strength dairy industry wastewater (5,000 and 10,000 mg/L-COD) and showed excellent performance by removing 99.7% COD. While the nanofiltration membrane was used for low-strength wastewater (40 and 450 mg/L-COD), and showed a COD removal efficiency of 98%. The fouling of nanofiltration and reverse osmosis were also investigated by Turan (2004) . The reduction in filtration efficiency resulted from an increase in the fouling layer and concentration polarization layer. The fouling behavior of dairy wastewater treatment by nanofiltration was investigated in another study by Luo et al. A rotating disk laboratory module with high shear and pressure was applied to treat the dairy wastewater using the NF270 membrane. The flux profile and permeate quality were not significantly affected by the presence of lipids, although adsorption fouling was marginally increased. Concentration polarisation was reduced by increased shear rates, which resulted in higher permeate fluxes and reduced permeability loss. The inorganic ions form aggregates with milk proteins, causing negligible inorganic fouling and alkaline cleaning could remove surface fouling. A high and stable flux was observed in DW treatment by NF under an extremely enhanced shear rate ( Luo et al., 2012 ). Also, integrated membrane systems process in sequential form showed better performance in terms of COD, TOC, and nutrient removal. The integrated systems consist of the sequential use of microfiltration (MF) and nanofiltration (NF) and MF and reverse osmosis (RO) under varying pressures to treat dairy effluent. The MF + NF system resulted in a 100% reduction in turbidity, 96% in colour, 58% in total Kjeldahl nitrogen (TKN), and 51% in COD. The MF + RO system resulted in a 100%, 100%, 94%, and 84% reduction in turbidity, colour, total dissolved nitrogen, and TOC, respectively. Consequently, the MF + RO system was more effective in retaining organic matter and total solids ( Bortoluzzi et al., 2017 ). Floatation is also a technique used for the treatment of dairy wastewater but merged with chemical-based coagulants for better efficiency ( Pereira et al., 2020 ). Adsorption is a method of wastewater treatment that effectively removes a significant quantity of non-degradable organic components from wastewater. The most often utilized adsorbent is activated carbon. Low-cost adsorbents such as rice husk, coal fly ash, and straw dust are used for wastewater treatment ( Sinha et al., 2019 ). In a previous study, activated charcoal achieved a maximum removal efficiency of 65% for COD and 67% for BOD in dairy effluent ( Kanawade and Bhusal, 2015 ). With the advantages of low energy consumption and cost-effective treatment, the physical treatment technology set the major disadvantages of limited contaminant removal like suspended particles and space requirement for sedimentation and aeration ( Yonar et al., 2018 ).

3.2 Chemical treatment technology

Chemical treatment includes processes such as pH balance and reagent oxidation, which are beneficial for the removal of soluble contaminants and colloids in wastewater. The dairy industry effluent exhibits a pH range of 4.7–11 and extreme values can have adverse effects on microbiological cells in biological reactions and increase the corrosion of pipelines. Consequently, it should be adjusted to mitigate its harmful effects ( Zainab et al., 2019 ). One approach to treat DW is electrochemical treatment, which entails the utilization of an iron electrode to treat simulated dairy effluent. It is highly effective in the treatment of nutrient-rich wastewater by reducing the COD and oil–grease in the aqueous phase ( Şengil and özacar, 2006 ). In another study by Kushwaha et al. (2010) , COD removal efficiency of appx. 70% was observed using the electrochemical treatment method with iron electrodes. A combination of electro-coagulation, electro-floatation, and electro-oxidation mechanisms were hypothesized as the main routes for COD depletion in dairy effluent. In another electrochemical-based treatment, H 2 O 2 /Fe 2+ molar ratio and H 2 O 2 /dairy wastewater ratio (DW) (mL/L) obtained the maximum COD removal of 93.93% within 90 min ( Davarnejad and Nikseresht, 2016 ). On the other hand, aluminum electrodes in the electro-coagulation process removed 60% COD in dairy wastewater ( Tchamango et al., 2010 ) while only 39% COD was removed by chemical coagulation ( Hamdani et al., 2005 ). Dairy wastewater also contains major amounts of fat, oil, and grease which are generated during unskinned milk production. The separation of fats from the wastewater can be done by increasing the temperature. Similarly, the proteins and lipids components in wastewater can be eliminated by the coagulation process. The flotation process by dissolved air technique is more effective due to the reduction of organic load, protein, and lipid colloids through the use of flocculants and coagulants. This method utilizes synthetic and costly compounds, which result in environmental issues. The use of organic coagulants like polyacrylamide [PAA] and polyferric sulphate [PFS] reduced the COD and turbidity level of dairy wastewater, with less or no environmental damage ( Loloei et al., 2014 ). The maximum BOD 5 and chemical oxygen demand removal efficiency was achieved at pH 8 and with poly aluminum chloride in 60 min in dairy wastewater ( Bazrafshan et al., 2016 ). Also, the utilization of UV irradiation helps in reducing the microbial load and dissolved organic method of dairy wastewater ( Passero et al., 2014 ). In a study conducted by Qin et al., UV irradiation and sodium hypochlorite both were tested for their efficiency in the treatment of dairy wastewater. The COD, total phosphorous, and total Khejdhal nitrogen displayed a slight reduction in their level after UV treatment but increasing values were observed in ammonium nitrogen. A similar trend was observed in the case of sodium hypochlorite treatment ( Qin et al., 2014 ). In another study, a combined aerated electrocoagulation process also showed a COD removal efficiency of 86.40% in the case of Al-Fe electrode combination with aeration at optimized conditions ( Akansha et al., 2020 ). The chemical-based treatment has the advantage of removing a wide range of contaminants, including dissolved and colloidal substances within less time duration. Despite this advantage, this treatment process has major setbacks in sludge production and disposal, handling and storage of potentially hazardous chemicals, and the treatment cost due to expensive chemicals ( Mohammed Bello et al., 2019 ).

3.3 Biological treatment technology

The biological treatment process includes the use of microorganisms to reduce the organic load present in the wastewater. The physical condition of the treatment system will depend on many parameters like pH, temperature, and oxygen amount, which need to be controlled to avoid the death of the microbial community for treatment. Certain nutrient loads should not exceed the tolerance level of microbes before the treatment. Also, there can be a presence of heavy metals in the dairy wastewater, which can damage the cells during the treatment, and reduce the efficiency ( Ramsuroop et al., 2024 ). Aerobic and anaerobic are two types of biological treatment methods ( Goli et al., 2019 ). Many studies have employed individual aerobic and anaerobic treatment technology and numerous investigations have used combined strategies to overcome the limitations of individual processes ( Goli et al., 2019 ; Ramsuroop et al., 2024 ).

The aerobic technique reduces the biological oxygen demand as well as phosphorous and nitrogen content in dairy wastewater. This process is also effective in removing the fats from the wastewater. The odor of wastewater is reduced when the ammonium nitrogen is converted to nitrates. In addition, the aerobic procedure will require aeration which requires high energy demand. Activated sludge treatment is one of the aerobic treatment methods, which employs the introduction of microbes in the wastewater. The microbes are then isolated using a clarifier or filter, while a fraction of the sludge is returned to the reactor ( Goli et al., 2019 ). Research has shown that activated sludge (including both bacterial and protozoan) was reported to be successful in decreasing organic compounds in dairy wastewater, the best performance was obtained at 45.4 kg O 2 d −1 ( Tocchi et al., 2012 ). This process had the advantages of easy operation and a light footprint ( Goli et al., 2019 ). Low environmental shock tolerance and toxin buildup are common issues in activated sludge operations. Additionally, sludge settling might hinder biomass recovery. Granular sludge, which generates solid spherical granules from microbes and flocs, has been used to address these shortcomings. These granules have enhanced shock resistance and settling qualities. Another drawback of activated sludge systems is the disposal of sludge ( Ramsuroop et al., 2024 ). Sequencing batch reactors (SBRs) combine many processes in one bioreactor ( Goli et al., 2019 ). These phases are sequential: filling, reacting, settling, decanting, and idling. Filling involves adding microbe-containing DW and microbes. The reaction step may include aerobic and anaerobic cycles. To do this, aeration and no aeration can be performed. At the settling stage, aeration and mixing are halted to allow suspended particles to separate from the treated water. In the decanting step, the supernatant fluid (treated wastewater) is removed. The idle stage is particularly important in multi-reactor systems with a delay between filling stages ( Goli et al., 2019 ; Ramsuroop et al., 2024 ). Studies have shown that SBRs may decrease COD levels by as much as 90%, whereas COD concentration varies from 400 to 2,500 mg/L. One investigation has successfully treated dairy wastewater using a hybrid up-flow–downflow reactor, maintaining stability even with an average organic loading rate of 10,000 mg COD/L/day. This system showcases the versatility of an SBR system by including both downflow pre-acidification chambers and up-flow methanation chambers. The process successfully converted 98% of the chemical oxygen demand into biogas, while also removing over 90% of ammonia and total phosphorus ( Malaspina et al., 1996 ). Additionally, research has been conducted using a sequencing batch reactor (SBR) in conjunction with membrane filtration to address these constraints. Nevertheless, the use of a membrane presents the added obstacle of membrane fouling, necessitating the implementation of further measures to minimize this potential problem. One disadvantage of SBRs is that they operate as a batch system, meaning that the reactors need to be loaded, unloaded, and cleaned for each batch. This leads to decreased production compared to a continuous system ( Ramsuroop et al., 2024 ). In a membrane bioreactor, the membrane is submerged within the reactor and another configuration is one where the membrane is placed on the exterior of the reactor with a recycle loop. It has been reported that an aerobic MBR may reduce the BOD 5 level in DWW by up to 99% and the ammonium levels by up to 99.9% ( Stepanov et al., 2019 ). In another investigation, aerobic MBR treated ice-cream wastewater with high levels of contaminants, namely, 13,300 mg COD/L and 6,500 mg BOD 5 /L. This treatment resulted in a reduction of over 95% in COD and BOD 5 levels, an 80% decrease in TP, and a decrease of over 96% in TN ( Scott and Smith, 1997 ). Like other membrane filtering systems, the primary concerns for a practical MBR system are the cost of the process, membrane fouling, and methods to manage fouling ( Goli et al., 2019 ). Other types of aerobic treatment reactors include tricking filters ( Goli et al., 2019 ) and rotating biological contractors ( Ramsuroop et al., 2024 ). The average treatment efficiency of trickling filters was 87.3%, 78.3%, and 27.9% without recirculation for COD, BOD, and total phosphorous while this treatment efficiency increased when recirculation was applied ( Zyłka et al., 2018 ). A significant concern is that trickling filters may get obstructed by the accumulation of ferric hydroxide and carbonates, resulting in a decrease in the activity of microbes. When there is an excessive amount of dairy wastewater, the fluid will get obstructed by dense biological and fat films ( Goli et al., 2019 ). The design of the rotating biological contactor (RBC) involves the use of circular discs, which promote the growth of a biofilm on its surface to allow the oxidation of organic molecules in the wastewater ( Kadu et al., 2013 ). The maximum COD removal efficiency of 94% in dairy wastewater was observed using a 3-tank biological contactor reactor ( Asha and Elakkiya, 2014 ). The RBC method has some advantages over the ASP when it comes to the treatment of dairy wastewater. The primary advantages of the RBC process are little power consumption, straightforward operation, and minimal maintenance requirements. However, in comparison to the trickling filter, RBC requires less area for treatment and incurs reduced running expenses ( Goli et al., 2019 ).

While the anaerobic treatment is mainly focused on decreasing the amount of organic matter and treating high concentrations of organic substances in wastewater. Anaerobic treatment can generate methane from wastewater that is rich in organic matter. Anaerobic technology is often used in anaerobic filters, sludge blanket reactors, and packed bed digestors ( Goli et al., 2019 ). In a study conducted by Rajagopal et al. (2013) , a reduction in 80% COD was achieved when treating a DW stream using anaerobic filters. Contrarily, this technique does not show effective results in removing the fat, oil, and greases (FOG) from high-fat-containing dairy wastewater ( Omil et al., 2003 ). This highlights the requirement of alternative technology for treating high organic-containing wastewater. Anaerobic packed bed reactors are another technology that was highly effective at reducing COD, BOD, and suspended solids up to 96%, 93%, and 90%, respectively. Up-flow anaerobic sludge blanket reactors (UASBRs) are one of the most used for the treatment of dairy wastewater. UASB reactors are used for treating wastewater that has COD up to 40 g/L. The reactor showed a COD reduction of 96.3% in 3 h ( Passeggi et al., 2012 ). A major hurdle involved in these reactors is the accumulation of organic matter in the sludge blanket, making the difficult for anaerobic bacteria to break down the FOG. Implementing a hydrolysis stage before the reaction or increasing the reaction time of the reactor would resolve the difficulty ( Ramsuroop et al., 2024 ). Another important treatment method is anaerobic digestion, 95% of the organic load in a waste stream can be turned into biogas (methane and carbon dioxide), while the rest is used for cell growth and maintenance. In addition, a small amount of sludge is generated in the anaerobic digestion process, reducing the difficulties related to sludge removal. Anaerobic digestion (AD) systems need nutrients, such as nitrogen and phosphorus, at levels much lower than those required by aerobic systems. One of the simple designs for AD design is a stirred tank reactor. Continuous stirred-tank reactors are often used for treating highly concentrated effluents, especially those containing a significant amount of suspended solids and chemical oxygen demand values over 30,000 mg/L. Biomass is not retained in this reactor, which means that the hydraulic retention time (HRT) and sludge retention time (SRT) cannot be distinguished. Consequently, extensive retention durations are required, based on the growth rate of the slowest-growing bacteria involved in the digesting process ( Goli et al., 2019 ). The up-flow anaerobic sludge blanket reactor is a very popular technique used for the treatment of wastewater. The advantage involved in an up-flow anaerobic sludge blanket reactor (ASBR) is less sludge production compared to an aerobic treatment system due to the slow growth rate of anaerobic organisms and good removal efficiency is achieved even at high loading rates and low temperatures. The procedure involves the use of anaerobic microorganisms in a single tank to treat wastewater, resulting in the near-total elimination of organic contaminants, solids, and oil and grease ( Sinha et al., 2019 ). COD and BOD removal of 77% and 87%, respectively was achieved in the reactor for the treatment of dairy wastewater. This technology removed the suspended solid and chlorides efficiently at the end of the treatment period ( Kavitha et al., 2013 ). The ASBR is a recently created batch reactor system that integrates the processes of digestion and the separation of particulates into a single vessel. The treatment of wastewater by anaerobic sequencing batch reactors involves four sequential steps: feeding, reaction, settling, and removal of treated wastewater. This form of reactor is widely used because of its notable advantages, such as its simplicity, effective quality control of wastewater, less settling time, and versatility in treating various types of effluents. Nevertheless, a significant drawback of ASBR is its suboptimal performance under heavy load conditions ( Sinha et al., 2019 ). At an organic loading of 1 g/L and a retention duration of 72 h, the COD reduction % at 35°C without additional seeds (pre-prepared culture media from synthetic milk waste and sewage) was reported to be 50%. While the COD removal efficiency of 83.33% with the addition of seeds was observed ( Dawood et al., 2011 ). Also, aerobic–anaerobic combined process allows the complete remediation of dairy wastewater as every stage focuses on different contaminants in the wastewater. The aerobic process reduces the ammonium, phosphate, hydrogen sulfide, and BOD of the wastewater while the anaerobic process reduces the COD and nitrate concentration in the effluent ( Ramsuroop et al., 2024 ).

3.4 Hybrid technology for dairy wastewater treatment

Biological approaches are often regarded as the most efficient means of treating dairy wastewater. Among these methods, aerobic systems are simpler to manage and regulate, while anaerobic systems generate less sludge and use less energy. It is advisable to construct a combined process that is particularly designed to meet the minimal criterion for discharging effluent ( Sinha et al., 2019 ). Many studies have used the hybrid or combined process for the effective treatment of dairy wastewater. Bazrafshan et al. used an inorganic prepolymerized-based coagulation and adsorption process on modified dried activated sludge for dairy wastewater treatment. The removal efficiency of most pollutants from raw dairy wastewater was high, still the coagulation process alone was not able to meet the discharge standards. The combination of adsorption in the treatment process enhanced the pollutant removal efficiency ( Bazrafshan et al., 2016 ). Another superior combination of chemical coagulation with the electro-fenton process was used by Zakeri et al. for the treatment of dairy wastewater. The removal efficiency of 90.3%, 87.25%, and 87% for COD, BOD 5 , and total suspended solids, respectively was noticed ( Zakeri et al., 2021 ). The catalyst-less and mediator-less membrane microbial fuel cell is a novel approach that allows for the simultaneous treatment of dairy sector effluent and the production of bioelectricity. In a study conducted by Mansoorian et al., two chambers, namely, an anaerobic anode and an aerobic cathode compartment were divided by a proton exchange membrane for dairy wastewater treatment. The findings indicate that the removal efficiency for COD improves from 78.21% to 90.46% and for BOD 5 it increases from 61.43% to 81.72% with increasing time ( Mansoorian et al., 2016 ). The ultraviolet (UV) photocatalytic treatment has the benefit of further eliminating organic compounds in wastewater, while its effectiveness is limited to low-strength effluent. Utilizing solar radiation for wastewater treatment shows potential for areas with abundant light. The treatment of wastewater with a combined anaerobic process (up-flow anaerobic sludge blanket reactor) and advanced oxidation processes (AOPs) hold a promising route toward efficient wastewater treatment. The combination of anaerobic and solar photocatalytic treatment achieved a 95% reduction in COD levels in the dairy effluent ( Rajesh Banu et al., 2008 ). Electrocoagulation is a popular technique for treating water and wastewater due to its combination of coagulation, flotation, and electrochemistry. The addition of air during the electrocoagulation process has an enhanced effect on reducing the COD of wastewater. Studies also showed an effective result when aerated electrocoagulation is combined with phytoremediation, 97.9% COD reduction was observed in dairy wastewater ( Akansha et al., 2020 ). Another study combines the use of UV irradiation, and sodium hypochlorite (NaClO) as a pretreatment step before microalgae-based treatment of dairy wastewater. The highest biomass productivity and lipid productivity of C. vulgaris reached 0.450 g L −1 day −1 and 51 mg L −1 day −1 in dairy wastewater, respectively ( Qin et al., 2014 ). From this, it can be concluded that combined hybrid technology with microalgae produced significant biomass with high-value product accumulation for various applications.

4 Role of microalgae in dairy wastewater treatment

4.1 an overview of the literature.

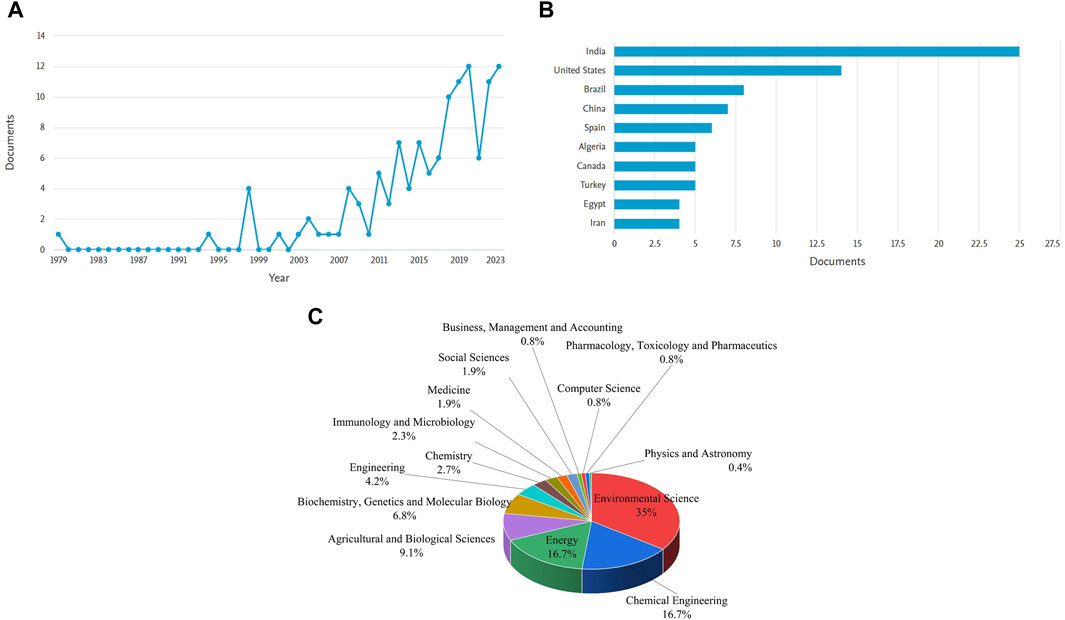

It was observed that research on dairy wastewater treatment was started initially in 1996 and started to increase tremendously from the 20th century. The publications of 12–24 documents on the treatment of dairy wastewater were published from 2019 to 2023 while only 3–7 documents were submitted from 2014 to 2018. A total of 127 research articles have been published as of the retrieval date of the data. India emerged as the market leader in the dairy industrial sector and its treatment, as evidenced by its increased involvement in this research domain. Guangzhou Institute of Energy Conversion has performed major work in this domain area of dairy wastewater treatment. With the increase in industrialization and urbanization, DW was listed among the polluted effluents. Dairy wastewater, on the other hand, is one of the most extensively researched and acceptable nutrient mediums that is utilized in the production and growth of microorganisms because it contains adequate amounts of phosphate and nitrogen sources ( Chokshi et al., 2016 ). There is a notable amount of studies being conducted at present to integrate microalgae with wastewater treatment. This shows that study in this area is becoming progressively more prevalent. It was also noted that over 34.90% of the study’s research was conducted in the field of Environmental science. This was followed by the fields of Chemical Engineering (16.73%), Energy (16.73%), Agricultural and Biological Sciences (9.12%), Biochemistry, Genetics and Molecular Biology (6.84%). This highlights that the field of dairy wastewater treatment primarily centers around the areas of Environmental Science, Chemical Engineering, and Energy (see Supplementary Tables S1–S4 ; Figure 2 ).

Figure 2 . Scientometric analysis obtained from scopus database for dairy wastewater treatment (A) Distribution of articles (B) countries active in the research area (C) research field area.

4.2 Keyword co-occurrence analysis

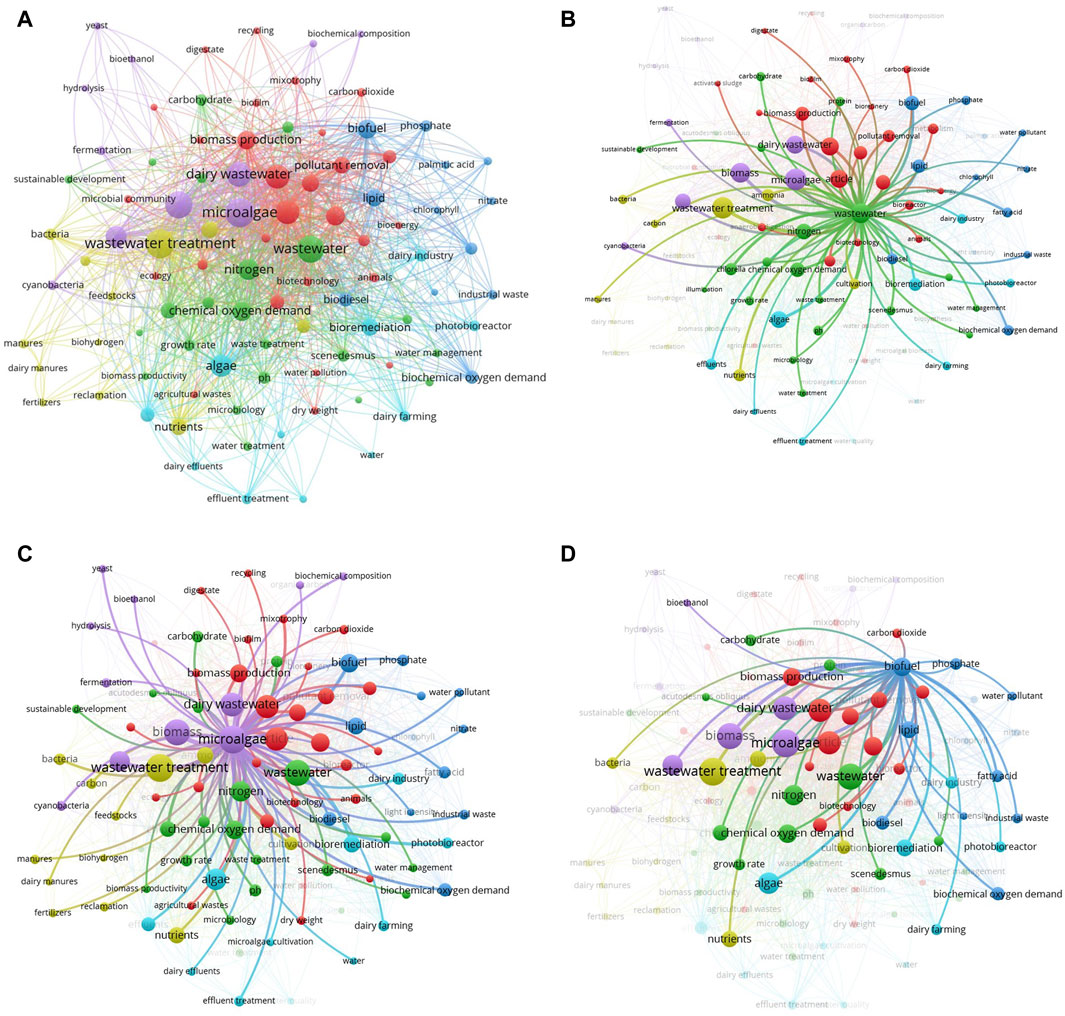

The search terms used throughout this area provide an in-depth understanding of disciplines that primarily focus on a certain domain. A network of interconnected keywords performs as an actual illustration of the interaction between them. The current study included the quantitative methods of “Author Keywords” and “Fractional Counting” in VOSviewer. A minimum criterion of five occurrences was established, resulting in the identification of 164 out of the total cumulative count of 1,688 terms. Afterward, the 164 keywords were refined by removing infrequent and repeated phrases such as “alga,” “animal,” “biofuels,” “biological oxygen demand analysis,” “fatty acids,” “effluent” and “biomass productions,” among others. Consequently, a total of 97 keywords were selected (see Supplementary Table S5 ) and represented in Figure 3 . The sizes of the vertices correspond to the frequency of occurrence of the keywords. Examples of bigger vertices in the graph are “wastewater treatment,” “wastewater,” “dairy wastewater,” and “microalgae,” indicating a greater frequency of occurrence. Moreover, it can be inferred that a major number of studies were conducted on dairy wastewater treatment using microalgae and biomass production. Moreover, the colors of the vertices distinguish the clusters; that is, every term is categorized into a unique group based on its distance from the other keywords. For example, the terms “dairy wastewater treatment,” “chemical oxygen demand,” “growth rate,” and “phycoremediation,” are represented by a single color, highlighting their significant interdependence. Furthermore, there might be a notable association between words that are part of other groups, such as “mixotrophy,” dairy wastewater,” “fermentation,” and “biofuel.” In many studies, DW was used as a nutrient source for microalgae growth and further, the biomass used for biofuel production ( Chokshi et al., 2016 ; Singh et al., 2023 ; Ravi Kiran et al., 2024 ). Singh et al. (2023) showed the potential of Monoraphidium sp. KMC4 biomass generated from DW towards bio-oil production. In another study, 29.6% of bio-oil yield was obtained from microalgae Messastrum gracile SVMIICT7 grown on dairy wastewater ( Ravi Kiran et al., 2024 ). Three major species, namely, Chlorella , Scenedesmus, and Acutodesmus were reported to be superior microalgae in DW treatment ( Chokshi et al., 2016 ; Daneshvar et al., 2019 ). Based on the grouping of keywords, the research on dairy wastewater treatment using microalgae may be categorized into three groups: chemical oxygen demand, biochemical composition, and biomass production.

Figure 3 . Significant keywords were observed in dairy wastewater treatment.

4.3 Mechanisms by which microalgae can treat wastewater

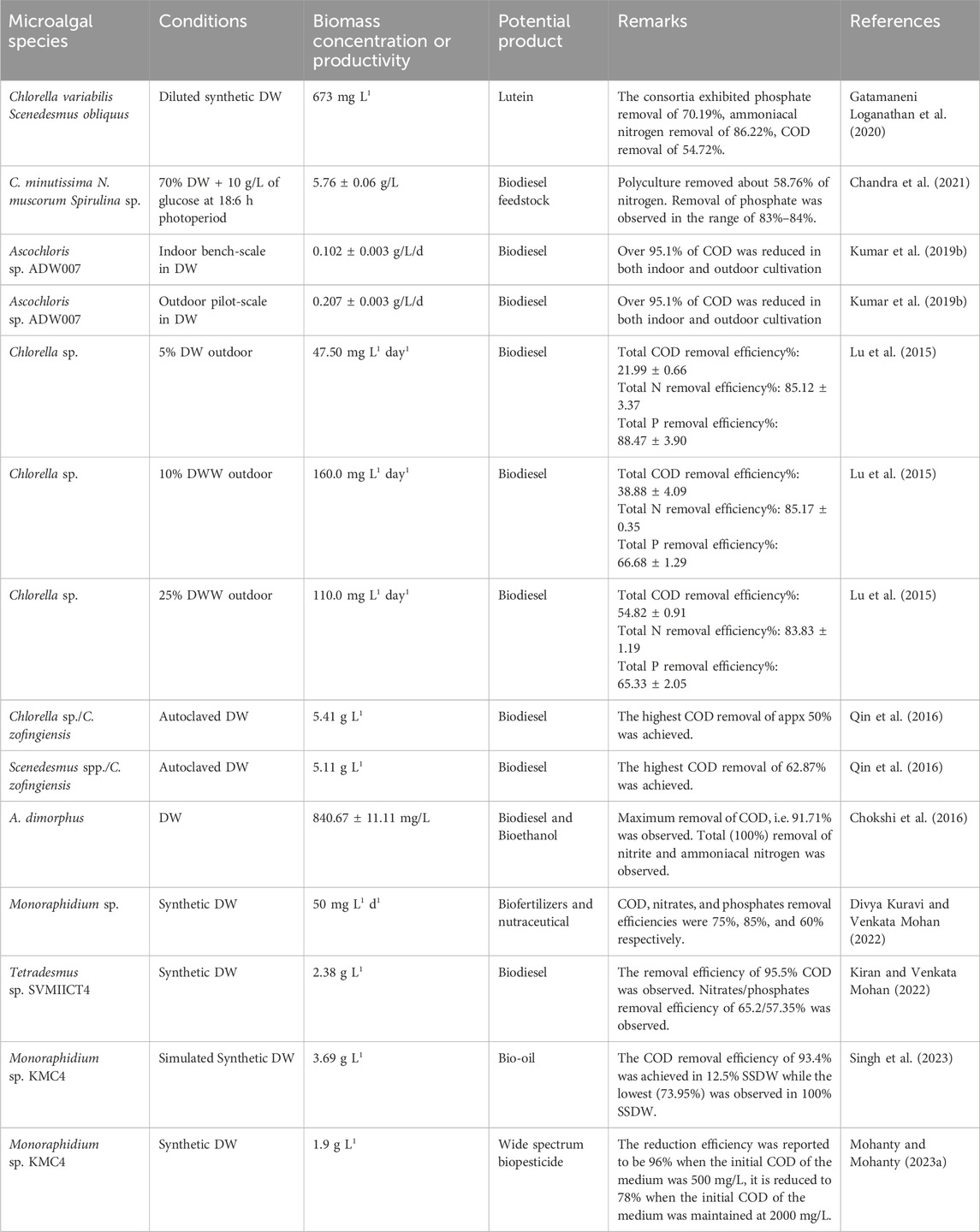

Microalgae cultivation and biomass production with the integration of wastewater treatment has garnered significant interest in the recent few years. Furthermore, the economic viability of the underlying methodology and operational procedures continues to pose challenges. Several investigations were conducted on the screening of potential microalgal strains ( Mohanty and Mohanty, 2023a ; Singh et al., 2023 ), the optimization of culture conditions ( Divya Kuravi and Venkata Mohan, 2021 ; Kiran and Venkata Mohan, 2021 ; 2022 ; Singh et al., 2023 ), the design of bioreactors for microalgal cultures ( Arora et al., 2021 ), and other factors to increase the lipid content of microalgae and promote their growth. To reduce overall costs, many studies were conducted on coupling microalgae growth with dairy wastewater treatment ( Singh et al., 2023 ; Ravi Kiran et al., 2024 ). The inorganic and organic nutrients present in the wastewater can be utilized by microalgae ( da Silva et al., 2021 ). Hence, this research topic has great potential and will be helpful in the development of a novel environmentally friendly method that combines both the production of microalgae and wastewater treatment ( Table 5 ).

Table 5 . Literature covering studies conducted on dairy wastewater treatment using microalgae.

4.3.1 Heterotrophic mode

In heterotrophic mode, the microalgae use the respiration process to obtain energy by organic compound oxidation ( Kim et al., 2019 ). Glucose, glycerol, and acetate are the main forms of carbon used for the cultivation of microalgae in heterotrophic mode. The use of glucose as an organic carbon source for microalgae culture has been widespread due to its superior energy in terms of adenosine triphosphate compared to other substrates. Acetate is also a common utilizable carbon source for growing microalgae in heterotrophic mode. Upon entry into the cytoplasm of microalgae cells, the process of acetate metabolism occurs via the acetylation of coenzyme A by acetyl-CoA synthetase. This reaction is a single-step process that utilizes a solitary ATP molecule, resulting in the formation of acetyl coenzyme A (acetyl-CoA). Two major pathways, namely, the glyoxylate cycle and Tricarboxylic Acid Cycle (TCA) further degrade the acetate to malate and citrate, respectively. Nevertheless, large amounts of acetate may exhibit toxicity against several cells, hence impeding their structure ( da Silva et al., 2021 ). Also, bacteria coexisting with microalgae were found to improve the degradation of nitrogen, phosphate, glucose, and chemical oxygen demand but with a trade-off in lipid productivity ( Zhang et al., 2012 ). Chlorella sp. HS2 high-density algal cultures were produced in heterotrophic cultivation mode using BG11 media with glucose in a fermenter with dark conditions. An increase of the model to a 5-L fermenter revealed that the culture depleted the phosphorus completely, which led to insufficient utilization of the nitrogen and carbon sources ( Kim et al., 2019 ). The respiration of organic-C during heterotrophic cultivation by microalgae generates CO 2 , which contributes to the greenhouse effect. On the other hand, the coexistence of heterotrophic and autotrophic microalgae in mixed cultures may result in a reduction of carbon dioxide emissions. This is due to the mutually beneficial nutrient requirements of each microorganism, whereby the heterotrophic species consume oxygen and generate carbon dioxide. The high quantities of organic compounds in the growth medium used for cultivating heterotrophic microalgae provide the possibility of invasion by competing bacteria and fungus, which may compromise the quality of the process and products. Heterotrophic growth of microalgae thus demands sterilization of media which can incur energy costs ranging from 20% to 30% of the overall costs of the production process. This expense might be recouped if the heterotrophic microalgae produce products with high market value ( da Silva et al., 2021 ). For the generation of high-market-value products, there is a requirement for scale-up technology, namely, a raceway pond for microalgae cultivation. It is very difficult to sterilize a huge amount of cultivation media for large ponds in heterotrophic mode. Also, the risk of bacterial and fungal contamination will increase in such open reactors ( Singh et al., 2023 ). From our knowledge, there are no industrial plants that use heterotrophic mode of cultivation to treat DW. However, additional investigation is required to augment biomass productivity and the productivity of high-value-added compounds when DW is used as a nutrient source to overcome the high market value.

4.3.2 Mixotrophic mode