What is a Paper Capacitor – Construction, Working & Applications

In every electronic circuit , resistors and capacitors are used as a passive component to resist and store electrical energy . Generally, Paper Capacitor is also known as condensers, which is made up of two conducting surfaces separated by an insulating material. This material is called the dielectric. Capacitors offer a low resistance path to A.C voltage and high resistance to D.C voltage from one circuit to another circuit. This capacitance of the circuit is stored in the form of an electric field. It opposes the flow of voltage in any electronic circuit and blocks the flow of direct current passing through it. Capacitors are manufactured with different packages, various types, and values based on the application.

What is the Paper Capacitor?

Definition: Paper capacitor is also known as a Fixed capacitor , in which paper is used as a dielectric medium, that stores energy in the form of the electrical field. These capacitors are used at power line frequency with a capacitance value of 1nF to 1uF. It stores a fixed amount of electric charge.

Working/Function

A paper capacitor is made up of two metallic plates with a dielectric material paper between them. It has positive and negative plates. When a small amount of electric charge is applied over the plates, the positive charge is attracted to one plate and a negative charge is attracted to another plate. This electrical energy is stored in the form of the electrical field. This stored electrical energy is used by the discharging of a capacitor. These are available in the range of 500pF to 50nF. These offer high leakage currents.

Paper Capacitor Values

The capacitance of the paper capacitor measured in terms of Farad’s(F). The capacitance range of this capacitor varies from 0.001 to 2.000 microfarad with a high voltage range of upto 2000V. Initially, the paper is used between the two aluminum sheets as a dielectric medium. But, now other materials like plastic are also used. These capacitors are available in the range of 300 picofarads to 4 microfarads with a working voltage of 600 volts.

Paper Capacitor Construction

The construction of the paper capacitor is divided into two types.

- Paper sheet capacitor

- Metalized paper capacitor

Paper Sheet Capacitor

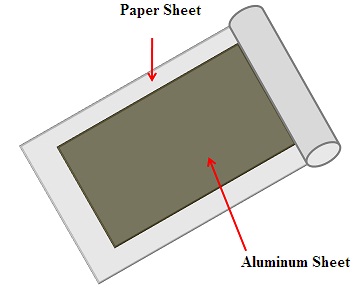

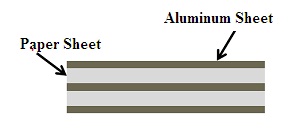

The construction of the paper sheet capacitor needs two aluminum sheets and a paper sheet. To protect from the outside environment, the paper sheet is covered with a wax or soaked with oil. Paper capacitors are the fixed capacitors that store a fixed amount of electric charge with a fixed capacitance value. The paper sheet placed between the aluminum sheets acts as a dielectric medium whereas aluminum acts as an electrode.

As the paper is a bad conductor of electricity, it doesn’t allow the flow of electric current between the aluminum sheets, which allows the electric field through it and acts as a barrier of electric current. The paper sheets and two aluminum sheets are rolled in the cylindrical shape and the entire cylinder is coated with wax or plastic resin to protect it from moisture in the air. The two-wire leads are taken from the ends of the two aluminum sheets.

Metalized Paper Capacitor

In a metalized paper capacitor, the paper is coated with a thin layer of zinc or aluminum and rolled in the form of a cylinder. The entire cylinder is coated with wax to protect it from the environment. The metalized paper acts as electrodes and paper act as a dielectric medium. This kind of capacitor coated with zinc can be destroyed easily due to the chemical action. Hence, aluminum is widely used in construction. The size of the metalized paper capacitor is very small when compared to the size of the paper sheet capacitor. Because it has a very thin layer of aluminum when compared to the aluminium used in the paper sheet capacitor.

Applications/Uses

Paper capacitors are widely used in various applications such as,

- High voltage and high current applications.

- used in electrical and electronic applications.

- Power conditioning systems to block DC signals and allow AC signals.

- used in-car audio systems to provide extra power to amplifiers when required

- used as sensors to measure air humidity, fuel levels, and mechanical strain.

- used in electronic noise filtering, signal coupling, and decoupling systems, remote sensing.

- used in signal processing systems such as tune circuits, speakers, dynamic random access memory (DRAM), radio receivers, and analog equalizers.

Advantages & Disadvantages

The advantage of using a paper capacitor is that provides a fixed value of capacitance. The value of the capacitance is fixed during manufacturing. The main disadvantage is, it absorbs moisture in the air and decreases the insulation resistance of the dielectric. As it absorbs moisture in the air, the dielectric medium is affected.

1). What is the Paper Capacitor used for?

A paper capacitor is an electronic device to store electrical energy in the form of an electric field. It is used in various high voltage and high current applications.

2). What is the Symbol of a Capacitor?

The passive electronic component used to store electric charges in the form of the electric field is called a capacitor. The capacitance is measured in Farads. When the capacitor has a larger capacitance, then it has the ability to store more electric charges.

3). What Metal is used in Capacitors?

The plates of the capacitor are made up of conducting material like Aluminum, tantalum, silver and other metals. The dielectric medium is made with insulating materials like paper, glass, rubber, ceramic or plastic depending upon the application.

4). What are the types of Capacitors?

There are 4 types of capacitors. They are,

- Ceramic capacitors

- Film capacitors

- Paper capacitors

- Dielectric capacitors

- Electrolytic capacitors.

5). How do you know if a capacitor is good?

To know the quality of the capacitor, we just need a digital multimeter with a high range and any one type of capacitor that is used in a device.

Connect the multimeter leads to the two ends of the capacitor plates. That is, connect the red lead of the multimeter to the positive plate of the capacitor and black leads to the negative plate. If the reading of the meter starts at zero and moves slowly towards infinity, then the capacitor is good.

Hence using a digital and analog multimeter, the capacitor can be tested to know that it is good or bad or open or short.

Share This Post:

- Electronics

- Communication

- Free Circuits

- Interview Questions

- ECE Projects

- EEE Projects

- Project Ideas

- Resistor Color Code Calculator

- Ohms Law Calculator

- Circuit Design

- Infographics

- What is a Paper Capacitor? | The Definitive Guide

Resistors and capacitors are used in every electronic circuit as passive components for resistance and storage of electrical energy. Paper capacitors are also commonly referred to as condensers. Which is composed of two operating surfaces separated by an insulating material. This material is called dielectric.

The capacitor produces low resistance for AC voltage while providing high resistance for DC voltage from one circuit to another. This capacitance of the circuit is stored in the form of an electric field. It resists the flow of voltage in any electronic circuit. And stops the flow of direct current passing through it.

In today’s article, we will see what is the construction of paper capacitors and what are its applications. And much more about it.

In This Post

What is a Paper Capacitor?

A paper Capacitor is also known as a fixed capacitor. In which paper is used as a dielectric medium. Which stores energy in the form of an electric field. Such a capacitor is used with a capacitance value of 1nF to 1uF at the power line frequency. It stores a fixed amount of electric charge.

Suggested Read: What is a Filter Capacitor? | Working of Filter Capacitor

Working of Paper Capacitor:

A paper capacitor is made up of two metallic plates. Which paper is used as the dielectric material between them? Which has positive and negative plates. When an electric charge is applied to this plate, the positive plate is attracted to one side and the negative charge is attracted to the other plate.

This electrical energy is stored in the form of an electric field. This collected electrical energy is used by discharging the capacitor. These range from 500pF to 50nF. This gives a high leakage current.

Paper Capacitor Values:

The capacitance of a paper capacitor is measured in the units of Faraday. The capacitance range of such a capacitor varies from 0.001 to 2.000 microfarads to a high voltage range of 2000V. At the beginning of this capacitor, the paper was used as a dielectric medium between two aluminum sheets.

But now other materials like plastic are also used in place of paper. This capacitor is readily available in the range of 300 picofarads to 4 microfarads with a working voltage of 600 volts.

Construction of Paper Capacitor:

The manufacture of paper capacitors is classified into two types as follows:

- Paper sheet capacitor.

- Metalized paper capacitor.

#1. Paper Sheet Capacitor:

The construction of this capacitor requires two pieces of aluminum sheet and one sheet of paper. The paper sheet is completely covered with wax to protect it from the open-air outside. A paper capacitor is a fixed capacitor that stores a fixed amount of electric charge with a fixed charge capacitance value.

The aluminum plate of the paper sheet is placed between the sheets which act as a dielectric medium. While aluminum acts as an electrode. Paper is a very poor conductor of electricity and does not allow an electric current to pass between the aluminum sheets.

Which allows the electric field through it. Acts as a barrier to electric current. Paper sheets and aluminum sheets are rotated into cylindrical shapes. The entire cylinder is coated with wax or plastic resin to protect it from outside air humidity and two-wire leads are taken from the ends of two aluminum sheets.

#2. Metalized Paper Capacitor:

In this paper capacitor, the paper is coated with a thin layer of zinc or aluminum. And rotated in the form of a cylinder. The entire cylinder is completely coated with wax to protect it from dust and moisture in the outside environment. Metallic paper electrodes and paper act as dielectric mediums.

This type of capacitor coated with zinc can be destroyed very easily due to chemical action. That is why aluminum is widely used in the construction of such capacitors. When paper sheet capacitors and metal paper capacitors are compared, the size of metal paper capacitors is smaller. This is because when compared to the aluminum wrapped in a paper sheet capacitor, it has a very thin layer of aluminum.

Advantages & Disadvantages of Paper Capacitor:

- The main advantage of using a paper capacitor is that it provides a fixed value of capacitance. And the value of capacitance during its production can be determined.

- The main disadvantage of paper capacitors is that they absorb moisture from the atmosphere. And reduces the insulation resistance of the dielectric. The dielectric medium affects it as it absorbs moisture from the atmosphere.

Suggested Read: Difference Between Capacitor And Battery │Capacitor vs Battery

Applications/Uses of Paper Capacitor:

The different uses of paper capacitors are as follows:

- In electrical and electronic circuits.

- In high voltage and high current applications.

- Used as a sensor to measure air humidity, fuel level, and mechanical stress.

- In-car audio systems are used to add extra power to the amplifier as needed.

- Used in electronic noise filtering, signal coupling, and decoupling systems, remote sensing.

- Blocks the DC signal in the power conditioning system and allows the AC signal to pass.

- Used in signal processing systems such as speakers, dynamic random access memory (DRAM), tune circuits, radio receivers, and analog equalizers.

Most Commonly Asked Questions:

What is the use of a paper capacitor?

A paper capacitor is a fixed capacitor. A paper capacitor is an electronic device for collecting or storing electrical energy in the form of an electric field. It is used in various high-voltage and high-current applications.

How is a paper capacitor made?

The construction of this paper capacitor requires two aluminum sheets and one sheet of paper. The paper acts as a dielectric between aluminum sheets. And aluminum sheets act as electrodes. The paper sheet acts as a barrier for electric current between the aluminum sheets.

What are the types of Capacitors?

There are 4 types of capacitors. They are,

- Ceramic capacitors.

- Dielectric capacitors.

- Film capacitors.

- Paper capacitors.

- Electrolytic capacitors.

What are the two types of capacitors?

Capacitors are divided into two main mechanical groups. One is a fixed capacitor with a value of fixed capacitance and the other is a variable capacitor with a value of a variable or adjustable capacitance. The most important group is fixed capacitors. Many got their names from dielectrics.

Like this post? Share it with your friends!

Suggested Read –

- Highway/Street Light Names And Functions

- Submersible Pump | Types of Submersible Pump

- What Is a Galvanometer | Construction of Galvanometer

- What is Hot Wire Instrument | Construction & Working of Hot Wire Instrument

Vishnu Patil

Hey, I am Vishnu Patil and I'm an Electrical Engineer and Electrical maestro. I have more than 10 years of experience with electricals. Through ElectricalGang I want to spread my knowledge with everyone else.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

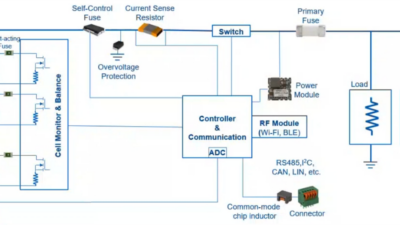

+86-75581785031

- Why Choose Us

- Medical Beauty

- Laser Measurement

- Medical Systems

- Communications Networks

- Industrial Control

- Other PCB ODM Products

- Smart Door Lock

- Communication Network Manufacturing

- Smart Watch

- Laser Distance Meter

- Laser Tape Measure

- Laser Range Finder Sight

- Energy Industry

- Laser Hair Removal Device

- Bluetooth Speaker

- PCB Fabrication

- Rapid Production

- Design and Engineering

- OEM/ODM Service

- Logistics and Fulfillment

- After Sales Services

- Supply Chain Services

- Test Services

IBE enables the world’s best brands. Through our unrivalled customer-centric approach, we partner with leading companies in numerous markets to deliver solutions for their most complex challenges.

IBe Industry Building, ShenZhen, China

What is a paper capacitor – a comprehensive guide

- September 30, 2023

- No Comments

Home » Blog » What is a paper capacitor – a comprehensive guide

What is a paper capacitor?

Paper capacitor is one of the basic types of capacitors. Typically, in a capacitor, the conducting materials are separated by a dielectric, and based on the variant used as the dielectric, different types of capacitors are formed. The structure of paper capacitor is similar to other capacitors, such as plastic capacitors. The only difference between the other capacitors and paper capacitors is that the dielectric chosen is paper. Paper capacitors are also called fixed capacitors, in which paper is used as a dielectric, which stores energy in the form of an electric field.

Paper capacitor is used in capacitance values of 1nF to 1uF at power line frequencies and it stores a fixed amount of charge. To care for or protect the dielectric from the environment, dip it in wax or oil.

Paper capacitance value

The capacitance of paper capacitor is measured in farads. The capacitance of paper capacitor ranges from 0.001 to 2.000 microfarads to the high voltage range of 2000V. In the beginning of this capacitor, paper was used as the dielectric between two aluminum sheets but now other materials like plastic are used instead of paper. Paper capacitor is readily available in the 300 picofarad to 4 microfarad range and operates at 600 volts.

How paper capacitors work?

Paper capacitors consist of two metal plates with paper used as the dielectric material between them. There are positive and negative plates in it and when a charge is applied to the plate, the positive plate is attracted to one side and the negative charge is attracted to the other plate. This electrical energy is stored in the form of an electric field, and this collected electrical energy is used by discharging the capacitor. These range from 500pF to 50nF. This results in high leakage current.

Structure of paper capacitor

There are two types of paper capacitors: paper capacitors and metallized paper capacitors.

Paper Capacitor The construction of this capacitor requires two sheets of aluminum and a piece of paper, which is completely covered with wax to protect it from the elements. A paper capacitor is a fixed capacitor that stores a fixed amount of charge at a fixed value of charge capacitance, with aluminum plates placed between sheets of paper that act as dielectrics, while aluminum acts as electrodes.

Paper is a very poor conductor of electricity, not allowing electric current to pass between the aluminum sheets, but allowing electric fields to pass through it, acting as a barrier to the flow of electricity. The paper and aluminum sheets are rotated into a cylinder shape, and the entire cylinder is coated with wax or plastic resin to protect it from the humidity of the outside air, and two wires are led from the ends of the two aluminum sheets.

Metallized paper capacitor In metalized paper capacitor, the paper is coated with a thin layer of zinc or aluminum and rotated in the form of a cylinder. The entire cylinder is completely coated with wax to protect it from dust and moisture in the external environment, with metal paper electrodes and paper acting as dielectrics.

Such zinc-coated capacitors are easily destroyed due to chemical effects, which is why aluminum is widely used in the manufacture of such capacitors. Compared with paper capacitors and metal paper capacitors, metal paper capacitors are smaller in size. This is because it has a very thin layer of aluminum compared to the aluminum wrapped in a paper capacitor.

Advantages and disadvantages of paper capacitor

The main advantage of using paper capacitor is that it provides a fixed capacitance value, and the capacitance value during their production can be determined; the main disadvantage of paper capacitor is that they absorb moisture from the atmosphere and reduce the insulation resistance of the dielectric. The dielectric affects it because it absorbs moisture from the atmosphere.

Applications of paper capacitor

- Electrical and electronic circuits

- High voltage and high current applications

- Used as a sensor to measure air humidity, fuel level and mechanical stress

- Used for car audio systems to add extra power to amplifiers as needed

- Used in electronic noise filtering, signal coupling and decoupling systems, remote sensing

- Used in signal processing systems such as speakers, dynamic random access memory (DRAM), tuning circuits, radio receivers and analog equalizers

The above is an introduction to paper capacitors. If you want to determine the quality of a capacitor, all you need is a wide-range digital multimeter and any type of capacitor in your device. Connect the multimeter leads to both ends of the capacitor plate. Connect the red lead of the multimeter to the positive plate of the capacitor and the black lead to the negative plate.

If the meter reading starts at zero and gradually increases to infinity, the capacitor is good. Therefore, a capacitor can be checked with a digital and analog multimeter to determine if it is good, bad, open, or short.

Paper capacitors are a type of capacitor that uses paper as an insulating material between the conductive plates. While they were once popular, they are prone to certain issues that can lead to failure. Here’s a clear and human-friendly explanation of why paper capacitors might fail:

Common Reasons for Paper Capacitor Failure: Moisture Absorption:

Issue: Paper capacitors can absorb moisture from the environment over time. Since paper is hygroscopic (meaning it absorbs water), this moisture can compromise the insulating properties of the paper. Effect: Increased moisture can cause a decrease in capacitance, increased leakage current, and eventually lead to a short circuit or total failure of the capacitor. Aging and Deterioration:

Issue: The paper used in these capacitors can deteriorate with age, especially when subjected to high temperatures or voltage stresses. Effect: As the paper breaks down, its insulating ability weakens, which can lead to decreased performance or capacitor failure. High Voltage Stress:

Issue: If a paper capacitor is exposed to voltages beyond its rated capacity, it can cause breakdown of the dielectric material (the paper). Effect: This can result in dielectric failure, where the capacitor either leaks, shorts, or fails to hold charge properly. Temperature Extremes:

Issue: Exposure to high temperatures can accelerate the degradation of the paper insulation. Similarly, very low temperatures can make the dielectric material brittle. Effect: Temperature extremes can cause physical damage or degradation, leading to failure of the capacitor. Electrical Overstress:

Issue: Frequent or prolonged exposure to voltages and currents higher than the capacitor’s specifications can cause internal breakdown. Effect: This overstress can damage the capacitor’s internal structure and lead to failure. Manufacturing Defects:

Issue: Defects during the manufacturing process, such as poor quality paper or improper winding, can lead to weak spots in the capacitor. Effect: These defects can cause early failure or unreliable performance.

Paper capacitors can fail due to issues like moisture absorption, aging and deterioration, high voltage stress, temperature extremes, electrical overstress, and manufacturing defects. These factors affect the insulating properties of the paper and can lead to a loss of performance or complete failure of the capacitor. While paper capacitors were once common, modern capacitors with more stable materials have largely replaced them in many applications.

The "strength" of a paper capacitor typically refers to its performance characteristics, including its ability to store and maintain electrical charge, as well as its durability and reliability in a circuit. Here’s a straightforward look at the strengths and limitations of paper capacitors:

Strengths of Paper Capacitors Cost-Effective: Paper capacitors were relatively inexpensive to manufacture, making them a cost-effective choice for many applications, especially in earlier electronic designs.

Good Performance for Low-Frequency Applications: They perform well in circuits where high-frequency performance is not critical. They were commonly used in power supply filters and other low-frequency applications.

Robust Physical Construction: Paper capacitors can be quite durable physically. Their construction involves layers of paper and foil, which can be rugged and withstand some mechanical stress.

High Voltage Ratings: Many paper capacitors are capable of handling high voltages, which made them suitable for use in high-voltage applications.

Limitations of Paper Capacitors Moisture Sensitivity: Paper is hygroscopic, meaning it absorbs moisture. Over time, this can degrade the dielectric properties of the capacitor, leading to a decrease in performance or failure.

Aging and Degradation: The paper dielectric can deteriorate with age, especially when exposed to high temperatures or excessive electrical stress. This can reduce the capacitor’s effectiveness and reliability.

Size and Bulkiness: Compared to modern capacitors, paper capacitors can be bulkier. Advances in technology have produced smaller, more efficient capacitors.

Limited High-Frequency Performance: Paper capacitors are less effective at higher frequencies compared to modern alternatives like ceramic or film capacitors. This makes them less suitable for high-frequency applications.

The strength of a paper capacitor lies in its cost-effectiveness, durability in low-frequency applications, and capability to handle high voltages. However, its performance can be affected by moisture, aging, and its bulkiness. While paper capacitors were once widely used, they have largely been replaced by more reliable and compact modern capacitors in many applications.

Paper capacitors, while less common today, offer several advantages that made them popular in the past. Here’s a clear and human-friendly look at the benefits of paper capacitors:

Advantages of Paper Capacitors Cost-Effective:

Benefit: Paper capacitors were relatively inexpensive to produce, which made them a budget-friendly option for many electronic devices, especially in earlier times when cost was a major concern. High Voltage Ratings:

Benefit: Many paper capacitors are designed to handle high voltages, making them suitable for applications where high voltage tolerance is necessary. This was particularly useful in power supply circuits and other high-voltage applications. Good Physical Durability:

Benefit: The construction of paper capacitors includes layers of paper and foil, which can be quite rugged. This durability means they could withstand some mechanical stress and handling during assembly and use. Simple Construction:

Benefit: The manufacturing process for paper capacitors is relatively straightforward, involving basic materials and techniques. This simplicity contributed to their low cost and ease of production. Stable Capacitance:

Benefit: In many applications, paper capacitors offer stable capacitance values over a wide range of operating conditions, which can be advantageous in maintaining circuit performance. Suitable for Low-Frequency Applications:

Benefit: Paper capacitors work well in low-frequency circuits, such as in power supply filtering and audio applications, where high-frequency performance is less critical.

- Why use tantalum capacitors in circuit board assembly

- What is decoupling capacitor? its types, function and layout

- PCB capacitors demystified everything you need to know

Leave a comment Cancel reply

Your email address will not be published. Required fields are marked *

Save my name, email, and website in this browser for the next time I comment.

The engineer’s guide to paper capacitors

This vintage capacitor type may be outdated, but it still has applications for certain high voltage, high current applications.

This article is part of The engineer’s complete guide to capacitors . If you’re unsure of what type of capacitor is best for your circuit, read How to choose the right capacitor for any application .

What is a paper capacitor?

Paper capacitors use paper as their dielectric. These are non-polarized capacitors that are often selected for high voltage and high current applications. They are used in power systems as coupling, decoupling and bypass capacitors and as energy reservoirs in automotive audio power amplifiers.

For an explanation of these terms, read: The engineer’s capacitor glossary: All terms and acronyms defined .

Operation of paper capacitors

Paper capacitors have two conductive plates separated by a paper dielectric. These electronic components are typically impregnated with wax or oil to eliminate air spaces between the cellulose fibers. Some are rated to operate 50,000 hours, which at 24/7 operation equates to about 5.7 years.

Capacitance values for paper capacitors range from about 0.001 µF to 10 µF, and maximum voltage ratings are less than 2000 V. These capacitors are susceptible to moisture, which can reduce their breakdown voltage. Metalized paper capacitors are available.

Applications of paper capacitors

Paper capacitor technology is considered vintage. Old radios and vacuum tube guitar amplifiers often used paper capacitors.

Alternatives to paper capacitors

Newer technology metal film capacitors or ceramic capacitors are superior alternatives to paper capacitors.

related topics

You might also like.

The 4 types of EV current sensors

July 15, 2024

Preparing for the 48-volt shift in automotive systems

June 5, 2024

What’s an aqueous battery, and how do they compare to current EV batteries?

May 31, 2024

Understanding battery management systems: Key components and functions

May 16, 2024

stay in the know

WatElectronics.com

Paper Capacitor Construction, Working, Advantages and Disadvantages

November 11, 2019 By WatElectronics

Paper capacitors are among one of the basic types of capacitors . Generally, in a capacitor the conducting material is separated by the dielectric. Based on the variant that is utilized as dielectric different types of capacitors are formed. The construction of this capacitor is similar to that of other capacitors, for example, plastic capacitors. The only difference between the other capacitors and this capacitor is that the dielectric chosen is of paper type.

What is a Paper Capacitor?

A capacitor that is constructed with a paper as the dielectric medium which is capable enough of storing the electric charge in it is defined as a paper capacitor. These are the capacitors that prefer fixed amounts of the charge value to be stored. Hence these capacitors categorized under the fixed type ones. To take care or protect the dielectric from the environmental effects it is soaked into wax or oil. These capacitors offer a fixed amount of capacitance.

Construction:

The construction of this type of capacitor is simple. It is based on the sheet of paper chosen. Hence based on the construction, these are classified into two types. They are:

- Paper Sheet

- Metalized Paper

Paper Sheet Type Capacitor

- In this case, the capacitor is constructed by placing a sheet of paper in between the aluminum sheets.

- The sheet of paper that is placed in between the aluminum sheets acts as the dielectric.

- The aluminum sheets act as the electrodes of the capacitor.

- Hence the sheet of paper is not a good conductor. So, the flow of the carriers and the passing of the electric current are not possible.

Paper Capacitor with Paper Sheet

- But the possibility is that the electric field is allowed to pass through it. Therefore the barrier between the electrodes is the sheet of paper.

- These sheets further are rolled in the form of a cylinder and the wire heads are attached. Finally, these are coated using wax or any plastic resin so that these acts as protectants from the environment moisture that is present in the air.

- In this way, this type of capacitor with a sheet of paper is constructed.

Metalized Paper Capacitor

- The paper sheet in this type of capacitor is built with the firm coating of either zinc or aluminum on it.

- After the coating is applied it is rolled just like the cylinder.

- These coated parts act as electrodes and the sheet of paper the same as before considered being dielectric.

- The roll of the cylinder is further provided with a coating of plastic resin or the wax. So that these capacitors are protected from the environmental constraints.

- While using the coating of zinc the drawback is that because of the chemical reactions zinc gets easily destroyed. So aluminum is widely preferred in this type of capacitor.

- Because of the direct coating on the paper in this type, the capacitor size is small compared to the paper sheet capacitor.

In this way, the capacitor with the metalized layer is constructed.

This is a capacitor that is constructed in such a way that its capacitance value is fixed. In this type of capacitor, there is the absence of electrolyte so it functions as a general parallel plate capacitor.

Capacitor Values

The value of this capacitor can be identified by following various steps:

- The number present on the capacitor represents the capacitance of the respective capacitor in terms of pico-farads.

- If in the 3-digit number the third represented number is ‘0’. Then the value represents P.

- If the printed number is of three digits then the third digit represents the number of zeroes.

Some of the capacitors follow color coding. Based on this the values of capacitors and their types are found. Paper capacitor ranges in between 300 pico Farads to 4 micro Farads. It’s working voltage exceeds rarely about 600 volts.

Paper Capacitor Advantages and Disadvantages

The advantages of this capacitor are classified under the category of the fixed value of capacitors. These capacitors provide fixed amounts of capacitance. The capacitance amount is fixed during manufacturing by the manufacturer.

The disadvantage or the drawback of using this capacitor is that it gets easily affected due to the moisture content that is present in the air. Because of these absorbing nature insulating nature of the dielectric becomes affected.

Applications

There are various applications of the paper capacitors. Some of them are:

- This can be used in various electrical and electronic applications.

- This can be utilized in filtering applications.

- In the high voltage required applications these are used.

- In the high current requirements, these capacitors are used.

This capacitor designing can be very simple as It is a fixed capacitor . Which paper capacitor you have recently used?

Types of Capacitors: Definition, Diagram, Working, Uses [PDF]

What is a capacitor.

Read Also: Different Types of Generators and Their Uses

What is Capacitance?

| C = Q/V |

Specifications of Capacitors

1. capacitance value, 2. voltage rating, 3. temperature co-efficient, 4. frequency range, 5. dielectric constant, 6. dielectric strength, 7. power factor, classification of capacitors, types of capacitors, fixed capacitors, #1 mica capacitors.

The constructional details are shown in the figure, from which it is clear that the alternate metal toils (1,3,5) and (2,4,6) are connected to form 2 separate sets, and a lead wire is connected to these two sets for External connection. The whole unit is placed in a metal casing or encapsulated with resin.

Applications of Mica Capacitors:

#2 ceramic capacitors.

In these capacitors, ceramic is used as a dielectric material. Ceramic material is formed in the form thin disc or tube by mixing barium titanate, talc, and magnesium silicate at different ratios.

Applications of Ceramic Capacitors:

#3 paper capacitors, applications of paper capacitors:, #4 plastic capacitors.

Constructional details of the plastic capacitor are shown in the figure, which consists of plastic as a dielectric material.

Two aluminum foils and plastic (polyester) film are kept alternately and rolled into a cylindrical shape. Copper leads are soldered on two metal foils and the whole unit is provided with resin molding.

Applications of Plastic Capacitors:

#5 electrolytic capacitors, 1. wet type electrolytic capacitor.

A thin film of oxide is deposited on the rod, which is connected to a positive terminal of the source. Thus rod acts as a positive terminal of the capacitor.

2. Dry Type Electrolytic Capacitor

Constructional details of dry-type electrolytic capacitors are shown in the figure, which contains two aluminum sheets separated by a layer of gauze separator saturated with a liquid chemical of boric acid. Copper lead wires are soldered to the aluminum foils for external connection.

So that foil acts as (+)ve terminal and other foil acts as (-)ve terminal. Now the foils are rolled into a cylindrical shape and enclosed in an aluminum or plastic tube.

Applications of Electrolytic Capacitors:

#6 film capacitor, #2 adjustable capacitors.

Ex: Trimmer & Padders.

Cup Type Adjustable Capacitor:

Applications of adjustable capacitors:, #3 variable capacitors, applications of variable capacitors:, difference between trimmers & padders, applications of capacitors, about saif m, 44 thoughts on “types of capacitors: definition, diagram, working, uses [pdf]”.

Please can you send me the PDF. regards Andrew

The PDF file has been sent to your inbox.

Very well! Can you please send me the Pdf-Document? Thank you.

You’re welcome. The PDF file has been sent to your inbox.

can you please send me the pdf thanks.

send pdf file, good information

Woow thank u so much you really helped me a lot💗💗

You’re welcome. Keep visiting 😉

THIS IS AMAZING.. ITS A BIG HELP FOR MY SELF STUDY AND FOR MY COMING TRAINING.. THANK YOU SO MUCH.. THANKS THE AUTHOR.. GOD BLESS YOU..

You’re most welcome. Keep visiting 😉

Oh wow, I got through several websites like electrical4u. but never had a chance to get this type of explanation to the knowledge great work.

Thanks for your valuable feedback. I appreciate it. Keep visiting 😉

This article was really helpful kindly email me this pdf

Thanks for your feedback. The PDF file has been sent to your inbox.

I need the pdf for the capacitor

It is really very helpful. Keep it up. If possible, could u please mail me this PDF?

Understood all the information

I’m glad it was helpful for you.

This is just nice i would like to have it in pdf

The PDf file has been sent to your inbox.

Me interesa descargarlo, muchas gracias

You’re welcome.

Please send me the PDF . Thanks

Please send me the PDF . Thanks!

i need the pdf file thanks

Hi Saif, nice work but how can we download this article?

Hi there, I just sent you the PDF file to your inbox.

Kindly send a PDF document

no download option for pdf on capacitors plz make it possible for download

Hi there, I just updated the article with a PDF file. Now you can download it.

Leave a Comment Cancel reply

What is a Capacitor, And What is Capacitance?

What is a Capacitor?

What is capacitance.

About Electrical4U

Leave a Comment Cancel reply

If you're seeing this message, it means we're having trouble loading external resources on our website.

If you're behind a web filter, please make sure that the domains *.kastatic.org and *.kasandbox.org are unblocked.

To log in and use all the features of Khan Academy, please enable JavaScript in your browser.

AP®︎/College Physics 2

Course: ap®︎/college physics 2 > unit 3, capacitors and capacitance.

- Parallel plate capacitors

- Dielectrics in capacitors

- Energy of a capacitor

- Capacitors in series

- Capacitors in parallel

Want to join the conversation?

- Upvote Button navigates to signup page

- Downvote Button navigates to signup page

- Flag Button navigates to signup page

30-second summary

Types of capacitors, typical values, application of capacitors, calculation of capacitors.

ε r = κ = ε/ε 0

Capacitors in series and parallel

Charging a capacitor, discharging a capacitor, energy stored in capacitor.

This is also equal to the total work done by the electric field on the charge when the capacitor discharges.

Capacitors in Hydraulic Analogy

In a hydraulic analogy , capacitors are equivalent to a tank with one connection at each end and a membrane dividing the tank in two lengthwise (a hydraulic accumulator). As the pump in the system begins pushing water, the membrane will stretch in response to the pressure from said water. The significance of the stretching is comparable to the amount of charge deposited on a capacitor. It should be fairly easy to see from this description that this membrane’s stretching represents the voltage drop in an electrical circuit, and the discharge of a capacitor is likewise comparable to the membrane returning to its original extent.

Capacitor with a Dielectric

Second, using a dielectric increases the maximum possible potential difference between the capacitor plates. Any insulating material, when subjected to a sufficiently large electric field, experiences a partial ionization that permits conduction through it. This is called dielectric breakdown. Note that, the dielectric strength of air is approximately 3 kV/mm. Many dielectric materials can tolerate stronger electric fields without breakdown than can air. Thus using a dielectric allows a capacitor to sustain a higher potential difference and so store greater amounts of charge and energy.

To see how this happens, suppose a capacitor has a capacitance when there is no material between the plates. When a dielectric material is inserted to completely fill the space between the plates, the capacitance increases to:

In the table below, we show some dielectric materials with their dielectric constant. Experiments indicate that all dielectric materials have κ e > 1. Note that every dielectric material has a characteristic dielectric strength which is the maximum value of the electric field before breakdown occurs and charges begin to flow.

Related Posts:

Privacy policy, editorial note, copyright notice.

It’s simple:

18.5 Capacitors and Dielectrics

Section learning objectives.

By the end of this section, you will be able to do the following:

- Calculate the energy stored in a charged capacitor and the capacitance of a capacitor

- Explain the properties of capacitors and dielectrics

Teacher Support

The learning objectives in this section will help your students master the following standards:

- (F) design construct, and calculate in terms of current through, potential difference across, resistance of, and power used by electric circuit elements connected in both series and parallel combinations.

In addition, the High School Physics Laboratory Manual addresses content in this section in the lab titled: Electric Charge as well as the following standards:

Section Key Terms

| capacitor | dielectric |

To present capacitors, this section emphasizes their capacity to store energy. Dielectrics are introduced as a way to increase the amount of energy that can be stored in a capacitor. To introduce the idea of energy storage, discuss with students other mechanisms of storing energy, such as dams or batteries. Ask which have greater capacity.

Explain that electrical capacitors are vital parts of all electrical circuits. In fact, all electrical devices have a capacitance even if a capacitor is not explicitly put into the device.

[BL] Have students define how the word capacity is used in everyday life. Have them look up the definition in the dictionary. Compare and contrast the everyday meaning with the meaning of the term in physics.

[OL] Ask students whether they have heard the word capacitor used in conjunction with electricity, such as in power stations or electric circuits. Have them describe how the word is used.

[AL] Discuss how a spring has a capacity to store mechanical energy. Discuss which properties of the spring would increase its capacity to store energy. Point out that these properties are intrinsic to the spring.

Consider again the X-ray tube discussed in the previous sample problem. How can a uniform electric field be produced? A single positive charge produces an electric field that points away from it, as in Figure 18.17 . This field is not uniform, because the space between the lines increases as you move away from the charge. However, if we combine a positive and a negative charge, we obtain the electric field shown in Figure 18.19 (a). Notice that, between the charges, the electric field lines are more equally spaced.

What happens if we place, say, five positive charges in a line across from five negative charges, as in Figure 18.27 ? Now the region between the lines of charge contains a fairly uniform electric field.

We can extend this idea even further and into two dimensions by placing two metallic plates face to face and charging one with positive charge and the other with an equal magnitude of negative charge. This can be done by connecting one plate to the positive terminal of a battery and the other plate to the negative terminal, as shown in Figure 18.28 . The electric field between these charged plates will be extremely uniform.

Let’s think about the work required to charge these plates. Before the plates are connected to the battery, they are neutral—that is, they have zero net charge. Placing the first positive charge on the left plate and the first negative charge on the right plate requires very little work, because the plates are neutral, so no opposing charges are present. Now consider placing a second positive charge on the left plate and a second negative charge on the right plate. Because the first two charges repel the new arrivals, a force must be applied to the two new charges over a distance to put them on the plates. This is the definition of work, which means that, compared with the first pair, more work is required to put the second pair of charges on the plates. To place the third positive and negative charges on the plates requires yet more work, and so on. Where does this work come from? The battery! Its chemical potential energy is converted into the work required to separate the positive and negative charges.

Although the battery does work, this work remains within the battery-plate system. Therefore, conservation of energy tells us that, if the potential energy of the battery decreases to separate charges, the energy of another part of the system must increase by the same amount. In fact, the energy from the battery is stored in the electric field between the plates. This idea is analogous to considering that the potential energy of a raised hammer is stored in Earth’s gravitational field. If the gravitational field were to disappear, the hammer would have no potential energy. Likewise, if no electric field existed between the plates, no energy would be stored between them.

If we now disconnect the plates from the battery, they will hold the energy. We could connect the plates to a lightbulb, for example, and the lightbulb would light up until this energy was used up. These plates thus have the capacity to store energy. For this reason, an arrangement such as this is called a capacitor . A capacitor is an arrangement of objects that, by virtue of their geometry, can store energy an electric field.

Various real capacitors are shown in Figure 18.29 . They are usually made from conducting plates or sheets that are separated by an insulating material. They can be flat or rolled up or have other geometries.

The capacity of a capacitor is defined by its capacitance C , which is given by

where Q is the magnitude of the charge on each capacitor plate, and V is the potential difference in going from the negative plate to the positive plate. This means that both Q and V are always positive, so the capacitance is always positive. We can see from the equation for capacitance that the units of capacitance are C/V, which are called farads (F) after the nineteenth-century English physicist Michael Faraday.

The equation C = Q / V C = Q / V makes sense: A parallel-plate capacitor (like the one shown in Figure 18.28 ) the size of a football field could hold a lot of charge without requiring too much work per unit charge to push the charge into the capacitor. Thus, Q would be large, and V would be small, so the capacitance C would be very large. Squeezing the same charge into a capacitor the size of a fingernail would require much more work, so V would be very large, and the capacitance would be much smaller.

Although the equation C = Q / V C = Q / V makes it seem that capacitance depends on voltage, in fact it does not. For a given capacitor, the ratio of the charge stored in the capacitor to the voltage difference between the plates of the capacitor always remains the same. Capacitance is determined by the geometry of the capacitor and the materials that it is made from. For a parallel-plate capacitor with nothing between its plates, the capacitance is given by

where A is the area of the plates of the capacitor and d is their separation. We use C 0 C 0 instead of C , because the capacitor has nothing between its plates (in the next section, we’ll see what happens when this is not the case). The constant ε 0 , ε 0 , read epsilon zero is called the permittivity of free space , and its value is

Coming back to the energy stored in a capacitor, we can ask exactly how much energy a capacitor stores. If a capacitor is charged by putting a voltage V across it for example, by connecting it to a battery with voltage V —the electrical potential energy stored in the capacitor is

Notice that the form of this equation is similar to that for kinetic energy, K = 1 2 m v 2 K = 1 2 m v 2 .

Watch Physics

Where does capacitance come from.

This video shows how capacitance is defined and why it depends only on the geometric properties of the capacitor, not on voltage or charge stored. In so doing, it provides a good review of the concepts of work and electric potential.

Grasp Check

If you increase the distance between the plates of a capacitor, how does the capacitance change?

- Doubling the distance between capacitor plates will reduce the capacitance four fold.

- Doubling the distance between capacitor plates will reduce the capacitance two fold.

- Doubling the distance between capacitor plates will increase the capacitance two times.

- Doubling the distance between capacitor plates will increase the capacitance four times.

Virtual Physics

Charge your capacitor.

In this simulation, you are presented with a parallel-plate capacitor connected to a variable-voltage battery. The battery is initially at zero volts, so no charge is on the capacitor. Slide the battery slider up and down to change the battery voltage, and observe the charges that accumulate on the plates. Display the capacitance, top-plate charge, and stored energy as you vary the battery voltage. You can also display the electric-field lines in the capacitor. Finally, probe the voltage between different points in this circuit with the help of the voltmeter.

True or false— In a capacitor, the stored energy is always positive, regardless of whether the top plate is charged with negative or positive charge.

Worked Example

Capacitance and charge stored in a parallel plate capacitor.

(a) What is the capacitance of a parallel-plate capacitor with metal plates, each of area 1.00 m 2 , separated by 0.0010 m? (b) What charge is stored in this capacitor if a voltage of 3.00 × 10 3 V is applied to it?

Strategy FOR (A)

Use the equation C 0 = ε 0 A d C 0 = ε 0 A d .

Entering the given values into this equation for the capacitance of a parallel-plate capacitor yields

This small value for the capacitance indicates how difficult it is to make a device with a large capacitance. Special techniques help, such as using very-large-area thin foils placed close together or using a dielectric (to be discussed below).

Strategy FOR (B)

Knowing C , find the charge stored by solving the equation C = Q / V C = Q / V , for the charge Q .

The charge Q on the capacitor is

This charge is only slightly greater than typical static electricity charges. More charge could be stored by using a dielectric between the capacitor plates.

What battery is needed to charge a capacitor?

Your friend provides you with a 10 μ F 10 μ F capacitor. To store 120 μ C 120 μ C on this capacitor, what voltage battery should you buy?

Use the equation C = Q / V C = Q / V to find the voltage needed to charge the capacitor.

Solving C = Q / V C = Q / V for the voltage gives V = Q / C V = Q / C . Inserting C = 10 μ F = 10 × 10 −6 F C = 10 μ F = 10 × 10 −6 F and Q = 120 μ C = 120 × 10 −6 C Q = 120 μ C = 120 × 10 −6 C gives

Such a battery should be easy to procure. There is still a question of whether the battery contains enough energy to provide the desired charge. The equation U E = 1 2 C V 2 U E = 1 2 C V 2 allows us to calculate the required energy.

A typical commercial battery can easily provide this much energy.

Practice Problems

What is the voltage on a 35 μF with 25 nC of charge?

- 8.75 × 10 −13 V

- 0.71 × 10 −3 V

- 1.4 × 10 −3 V

- 1.4 × 10 3 V

Which voltage is across a 100 μF capacitor that stores 10 J of energy?

- −4.5 × 10 2 V

- 4.5 × 10 2 V

- ±4.5 × 10 2 V

- ±9 × 10 2 V

Dielectrics

Explain that dielectric is short for dielectric material , which has specific electrical properties to be discussed in this section. The word dielectric is used to indicate the energy-storage capacity of a material. Remind students that insulator is used to indicate the ability of a material to prevent the passage of electric charge.

[BL] [OL] Point out that the prefix di means two or double. Combined with the word electric , this implies that a dielectric can have two electric charges.

[AL] Ask students whether they know of other words that use the prefix di in science (diatomic, carbon dioxide, dipole, …).

Before working through some sample problems, let’s look at what happens if we put an insulating material between the plates of a capacitor that has been charged and then disconnected from the charging battery, as illustrated in Figure 18.30 . Because the material is insulating, the charge cannot move through it from one plate to the other, so the charge Q on the capacitor does not change. An electric field exists between the plates of a charged capacitor, so the insulating material becomes polarized, as shown in the lower part of the figure. An electrically insulating material that becomes polarized in an electric field is called a dielectric .

Figure 18.30 shows that the negative charge in the molecules in the material shifts to the left, toward the positive charge of the capacitor. This shift is due to the electric field, which applies a force to the left on the electrons in the molecules of the dielectric. The right sides of the molecules are now missing a bit of negative charge, so their net charge is positive.

Point out the positive and negative surface charge on each side of the dielectric. Discuss with students that the electric-field lines are drawn so that they touch the surface charges, because electric-field lines always start or terminate on a charge. Thus, fewer electric-field lines will traverse the dielectric, meaning the electric field is weaker inside the dielectric.

All electrically insulating materials are dielectrics, but some are better dielectrics than others. A good dielectric is one whose molecules allow their electrons to shift strongly in an electric field. In other words, an electric field pulls their electrons a fair bit away from their atom, but they do not escape completely from their atom (which is why they are insulators).

Figure 18.31 shows a macroscopic view of a dielectric in a charged capacitor. Notice that the electric-field lines in the capacitor with the dielectric are spaced farther apart than the electric-field lines in the capacitor with no dielectric. This means that the electric field in the dielectric is weaker, so it stores less electrical potential energy than the electric field in the capacitor with no dielectric.

Where has this energy gone? In fact, the molecules in the dielectric act like tiny springs, and the energy in the electric field goes into stretching these springs. With the electric field thus weakened, the voltage difference between the two sides of the capacitor is smaller, so it becomes easier to put more charge on the capacitor. Placing a dielectric in a capacitor before charging it therefore allows more charge and potential energy to be stored in the capacitor. A parallel plate with a dielectric has a capacitance of

where κ κ ( kappa ) is a dimensionless constant called the dielectric constant . Because κ κ is greater than 1 for dielectrics, the capacitance increases when a dielectric is placed between the capacitor plates. The dielectric constant of several materials is shown in Table 18.1 .

| Material | Dielectric Constant ( ) |

|---|---|

| Vacuum | 1.00000 |

| Air | 1.00059 |

| Fused quartz | 3.78 |

| Neoprene rubber | 6.7 |

| Nylon | 3.4 |

| Paper | 3.7 |

| Polystyrene | 2.56 |

| Pyrex glass | 5.6 |

| Silicon oil | 2.5 |

| Strontium titanate | 233 |

| Teflon | 2.1 |

| Water | 80 |

Emphasize that the electric-field lines in the dielectric are less dense than in the capacitor with no dielectric, which shows that the electric field is weaker in the dielectric.

Capacitor for Camera Flash

A typical flash for a point-and-shoot camera uses a capacitor of about 200 μ F 200 μ F . (a) If the potential difference between the capacitor plates is 100 V—that is, 100 V is placed “across the capacitor,” how much energy is stored in the capacitor? (b) If the dielectric used in the capacitor were a 0.010-mm-thick sheet of nylon, what would be the surface area of the capacitor plates?

Given that V = 100 V V = 100 V and C = 200 × 10 −6 F C = 200 × 10 −6 F , we can use the equation U E = 1 2 C V 2 U E = 1 2 C V 2 , to find the electric potential energy stored in the capacitor.

Inserting the given quantities into U E = 1 2 C V 2 U E = 1 2 C V 2 gives

This is enough energy to lift a 1-kg ball about 1 m up from the ground. The flash lasts for about 0.001 s, so the power delivered by the capacitor during this brief time is P = U E t = 1.0 J 0.001 s = 1 kW P = U E t = 1.0 J 0.001 s = 1 kW . Considering that a car engine delivers about 100 kW of power, this is not bad for a little capacitor!

Because the capacitor plates are in contact with the dielectric, we know that the spacing between the capacitor plates is d = 0.010 mm = 1.0 × 10 −5 m d = 0.010 mm = 1.0 × 10 −5 m . From the previous table, the dielectric constant of nylon is κ = 3.4 κ = 3.4 . We can now use the equation C = κ ε 0 A d C = κ ε 0 A d to find the area A of the capacitor.

Solving the equation for the area A and inserting the known quantities gives

This is much too large an area to roll into a capacitor small enough to fit in a handheld camera. This is why these capacitors don’t use simple dielectrics but a more advanced technology to obtain a high capacitance.

With 12 V across a capacitor, it accepts 10 mC of charge. What is its capacitance?

A parallel-plate capacitor has an area of 10 cm 2 and the plates are separated by 100 μ m . If the capacitor contains paper between the plates, what is its capacitance?

- 3.3 × 10 −10 F

- 3.3 × 10 −8 F

- 3.3 × 10 −6 F

- 3.3 × 10 −4 F

Check Your Understanding

- The capacitance will remain the same.

- The capacitance will double.

- The capacitance will increase four times.

- The capacitance will increase eight times.

- It will increase by a factor of two.

- It will increase by a factor of four.

- It will increase by a factor of six.

- It will increase by a factor of eight.

This book may not be used in the training of large language models or otherwise be ingested into large language models or generative AI offerings without OpenStax's permission.

Want to cite, share, or modify this book? This book uses the Creative Commons Attribution License and you must attribute Texas Education Agency (TEA). The original material is available at: https://www.texasgateway.org/book/tea-physics . Changes were made to the original material, including updates to art, structure, and other content updates.

Access for free at https://openstax.org/books/physics/pages/1-introduction

- Authors: Paul Peter Urone, Roger Hinrichs

- Publisher/website: OpenStax

- Book title: Physics

- Publication date: Mar 26, 2020

- Location: Houston, Texas

- Book URL: https://openstax.org/books/physics/pages/1-introduction

- Section URL: https://openstax.org/books/physics/pages/18-5-capacitors-and-dielectrics

© Jun 7, 2024 Texas Education Agency (TEA). The OpenStax name, OpenStax logo, OpenStax book covers, OpenStax CNX name, and OpenStax CNX logo are not subject to the Creative Commons license and may not be reproduced without the prior and express written consent of Rice University.

- IIT JEE Study Material

- Capacitor Types And Capacitance

Capacitor - Types of Capacitor and Capacitance

What is a capacitor.

A capacitor is a device in which electrical energy can be stored. It is an arrangement of two conductors, generally carrying charges of equal magnitudes and opposite signs, and separated by an insulating medium. The non-conductive region can either be an electric insulator or vacuum, such as glass, paper or air, or a semi-conductor called a dielectric.

Capacitors vary in shape and size, and they have many important applications in electronics.

Related Physics Concepts:

- Capacitor, Types and Capacitance

- Combination of Capacitors

- Energy Stored in a Capacitor

What Are Capacitors Used for?

- Storing electric potential energy such as batteries.

- Filtering out unwanted frequency signals

- Delaying voltage changes when coupled with resistors.

- Used as a sensing device.

- Used in the audio system of the vehicle.

- Used to separate AC and DC.

One of the conductors has a positive charge of +Q, and it is at potential +V, whereas the other has an equal negative charge -Q and is at potential -V.

Charge on Capacitor

Note: The charge on the capacitor is Q.

The total charge/the net charge on the capacitor is –Q + Q = 0.

Circuit Symbols

Charge Distribution between Capacitors – Video Lesson

Capacitance

The charge on the capacitor (Q) is directly proportional to the potential difference (V) between the plates, i.e., \(\begin{array}{l}Q\alpha V\end{array} \) or Q = CV.

The constant of proportionality (C) is termed as the capacitance of the capacitor .

Dimensional Formula and Unit of Capacitance

- Unit of Capacitance: Farad (F)

The capacitor value can vary from a fraction of a picofarad to more than a microfarad. Voltage levels can range from a couple to a substantial couple of hundred thousand volts.

- Dimensional Formula: M -1 L -2 I 2 T 4

Commonly Used Scales

- \(\begin{array}{l}\mu F\end{array} \) = 10 -6 F

- nF = 10 -9 F

- pF = 10 +2 F

Factors Affecting Capacitance

Capacitance depends on the following factors:

- Shape and size of the conductor

- Medium between them

- Presence of other conductors near it

Calculation of Capacitance

We will try to calculate the capacitance of differently shaped capacitors , and the steps are as follows:

- Assume the charge on the conductors (Q)

- Calculate the electric field between the plates (E)

- Calculate the potential difference from the electric field (V)

- Apply the relation, \(\begin{array}{l}C=\frac{Q}{V}\end{array} \)

Types of Capacitors

Parallel plate capacitor, spherical capacitor, cylindrical capacitor.

The parallel plate capacitor consists of two metal plates of area A, and is separated by a distance d. The plate on the top is given a charge +Q, and that at the bottom is given the charge –Q. A potential difference of V is developed between the plates.

The separation is very small compared to the dimensions of the plate, so the effect of bending outward of electric field lines at the edges and the non-uniformity of surface charge density at the edges can be ignored.

The charge density on each plate of the parallel plate capacitor has a magnitude of σ.

From Gauss’s law, E = Q/ε 0 A

Also, E = V/d

Now, taking field due to the surface charges outside the capacitor,

This result is valid for the vacuum between the capacitor plates. For other media, then capacitance will be \(\begin{array}{l}C = \frac{kA\varepsilon _0}{d}\end{array} \) , where k is the dielectric constant of the medium,

If there is a vacuum between the plates, k = 1.

Parallel Plate Capacitor – Video Lesson

Let’s consider a spherical capacitor that consists of two concentric spherical shells. Suppose the radius of the inner sphere, R in = a and the radius of the outer sphere, R out = b. The inner shell is given a positive charge +Q, and the outer shell is given –Q.

Consider a solid cylinder of radius a surrounded by a cylindrical shell, b. The length of the cylinder is l and is much larger than a-b to avoid edge effects. The capacitor is charged so that the charge on the inner cylinder is +Q and the outer cylinder is –Q.

From Gauss’s law,

Where λ = Q/l, linear charge density

The potential difference of cylindrical capacitor is given by,

Where, we have chosen the integration path to be along the direction of the electric field lines. As expected, the outer conductor with a negative charge has a lower potential, which gives

Once again, we see that the capacitance C depends only on the geometrical L, a and b.

Problems on Capacitor and Capacitance

Problem 1: Find the capacitance of a conducting sphere of radius R.

Problem 2: A parallel plate air capacitor is made using two plates 0.2 m square, spaced 1 cm apart. It is connected to a 50 V battery.

- What is the capacitance?

- What is the charge on each plate?

- What is the electric field between two plates?

- If the battery is disconnected and then the plates are pulled apart to a separation of 2 cm, what are the answers to the above parts?

- \(\begin{array}{l}C_{0} = \frac{\varepsilon_{0}A}{d_{0}} = \frac{8.85\times10^{-12}\times0.2\times0.2}{0.01}\end{array} \) = 35.4 x 10 -12 F

- \(\begin{array}{l}Q_0=C_{0}V_{0}=(35.4\times 10^{-12}\times50)C = 1.77\times10^{-5}C = 1770 \times 10^{-12}C\end{array} \)

- \(\begin{array}{l}E_{0} = \frac{V_{0}}{d_{0}} =\frac{50}{0.01} = 5000V/m\end{array} \)

- If the battery is disconnected, the charge on the capacitor plates remains constant, while the potential difference between plates can change.

Problem 3: A parallel plate conductor connected in the battery with a plate area of 3.0 cm 2 and plate separation of 3 mm if the charge stored on the plate is 4.0pc. Calculate the voltage of the battery.

Area A = 3.0 cm 2 = 3.0 × 10 -4 m 2

C a = 8.85 × 10 -13

Dielectrics and Capacitance

What are dielectrics.

It is an insulating material (non-conducting) which has no free electrons. But a microscopic displacement of charges is observed in the presence of an electric field. It is found that the capacitance increases as the space between the conducting plates is filled with dielectrics.

Polar and Non-polar Dielectrics

Each atom is made of a positively charged nucleus surrounded by electrons. If the centre of the negatively charged electrons does not coincide with the centre of the nucleus, then a permanent dipole (separation of charges over a distance) moment is formed. Such molecules are called polar molecules. If a polar dielectric is placed in an electric field, the individual dipoles experience a torque and try to align along the field.

In non-polar molecules, the centres of the positive and negative charge distributions coincide. There is no permanent dipole moment created. But in the presence of an electric field, the centres are slightly displaced. This is called induced dipole moments.

Polarization of a Dielectric Slab

It is the process of inducing charges on the dielectric and creating a dipole moment. Dipole moment appears in any volume of a dielectric. \(\begin{array}{l}\text{The polarization vector}\ \overrightarrow{p}\ \text{is defined as the dipole moment per unit volume.}\end{array} \)

Dielectric Constant

\(\begin{array}{l}\text{Let}\ \overrightarrow{{{E}_{0}}}\ \text{be the electric field due to external sources and}\ \overrightarrow{{{E}_{p}}}\end{array} \) be the field due to polarization (induced). The resultant field is:

The induced electric field is opposite in direction to the applied field. But the resultant field is in the direction of the applied field with reduced magnitude.

\(\begin{array}{l}\overrightarrow{E}=\frac{\overrightarrow{{{E}_{0}}}}{K}\end{array} \) K is called the dielectric constant or relative permittivity of the dielectric. For vacuum, \(\begin{array}{l}\overrightarrow{{{E}_{p}}}=0, K = 1\end{array} \) . It is also denoted by ε.

Effect of Dielectric on Capacitance

Dielectric slabs in series.

A parallel plate capacitor contains two dielectric slabs of thickness d 1 , d 2 and dielectric constant k 1 and k 2, respectively. The area of the capacitor plates and slabs is equal to A.

Considering the capacitor as a combination of two capacitors in series, the equivalent capacitance C is given by:

Dielectric Slabs in Parallel

Consider a capacitor with two dielectric slabs of the same thickness d placed inside it, as shown in the figure. The slabs have dielectric constants k 1 and k 2 and areas A 1 and A 2, respectively. Treating the combination as two capacitors in parallel,

C = C 1 + C 2

Dielectric and Vacuum

If there exists a dielectric slab of thickness t inside a capacitor whose plates are separated by distance d, the equivalent capacitance is given as:

The equivalent capacitance is not affected by changing the distance of the slab from the parallel plates. If the slab is of metal, the equivalent capacitance is: \(\begin{array}{l}C=\frac{{{\varepsilon }_{0}}A}{d-t}\end{array} \) .

Problems on Capacitance and Dielectrics

Problem 1: Three capacitors of 10μF each are connected, as shown in the figure. Two of them are now filled with dielectric with K = 2, and K = 2.5. Find the equivalent capacitance.

After the insertion of dielectrics,

C 1 = 10μF; C 2 = KC 0 = 2 x 10 = 20μF; C 3 = KC 0 = 2.5 x 10 = 25 μF

Problem 2: Find the equivalent capacitance of the system shown in the figure (assume square plates).

Taking K 1 = 2 to be series in K 2 = 3

\(\begin{array}{l}\Rightarrow \,\,\frac{1}{{{c}_{left}}}=\frac{1}{\frac{(2){{\varepsilon }_{0}}\left\{ (L)\left( \frac{L}{3} \right) \right\}}{\left( \frac{d}{3} \right)}}+\frac{1}{\frac{(3){{\varepsilon }_{0}}\left\{ (L)\left( \frac{L}{3} \right) \right\}}{\left( \frac{2d}{3} \right)}}\Rightarrow \,\,\,\,{{C}_{left}}=\frac{6{{\varepsilon }_{0}}{{L}^{2}}}{7d}\end{array} \) Now

Now, C left and C right are in parallel.

Problem 3: Calculate the effective capacitance connected in series and parallel. The capacitors are connected to a 40 V battery. Also, calculate the voltage across the capacitors for each connection type.

When capacitors are connected in series,

For the 12 F capacitor:

For the 6F capacitor:

When capacitors are connected in parallel,

The voltage is the same as 40V across each capacitor.

You might also be interested in the following:

- HC Verma Solutions

- HC Verma Solutions Part 1

- HC Verma Solutions Part 2

Capacitor and Its Capacitance, Types of Capacitors

Combination of Charged Capacitor & Circuit Theory

Charging of a Capacitor – Electrostatic Potential and Capacitance

Watch this Video for More Reference

Electrostatics and Capacitor – Important Topics

Electrostatics and Capacitor – Important Questions

Frequently Asked Questions on Types of Capacitors and Capacitance

Define the capacitance of a capacitor..

The capacitance of a capacitor is the ratio of the magnitude of the charge on either conductor or the potential difference between the conductors forming the capacitor.

How can the capacitance of the parallel plate capacitor be increased?

The capacitance of the parallel plate capacitor can be increased in the following ways: Increasing the area of the plates. Decreasing the distance between the plates. Using a medium of higher dielectric constant.

Does the capacitance of the capacitor change when the charge on it is doubled?

The capacitance is independent of charge, therefore, it remains the same.

What happens to the charge on the parallel plate capacitor when the potential difference between the plates is doubled?

The charge also gets doubled.

Put your understanding of this concept to test by answering a few MCQs. Click ‘Start Quiz’ to begin!

Select the correct answer and click on the “Finish” button Check your score and answers at the end of the quiz

Visit BYJU’S for all Jee related queries and study materials

Your result is as below

Request OTP on Voice Call

Leave a Comment Cancel reply

Your Mobile number and Email id will not be published. Required fields are marked *

Post My Comment

Register with Aakash BYJU'S & Download Free PDFs

Register with byju's & watch live videos.

Information

- Author Services

Initiatives

You are accessing a machine-readable page. In order to be human-readable, please install an RSS reader.

All articles published by MDPI are made immediately available worldwide under an open access license. No special permission is required to reuse all or part of the article published by MDPI, including figures and tables. For articles published under an open access Creative Common CC BY license, any part of the article may be reused without permission provided that the original article is clearly cited. For more information, please refer to https://www.mdpi.com/openaccess .

Feature papers represent the most advanced research with significant potential for high impact in the field. A Feature Paper should be a substantial original Article that involves several techniques or approaches, provides an outlook for future research directions and describes possible research applications.

Feature papers are submitted upon individual invitation or recommendation by the scientific editors and must receive positive feedback from the reviewers.

Editor’s Choice articles are based on recommendations by the scientific editors of MDPI journals from around the world. Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. The aim is to provide a snapshot of some of the most exciting work published in the various research areas of the journal.

Original Submission Date Received: .

- Active Journals

- Find a Journal

- Proceedings Series

- For Authors

- For Reviewers

- For Editors

- For Librarians

- For Publishers

- For Societies

- For Conference Organizers

- Open Access Policy

- Institutional Open Access Program

- Special Issues Guidelines

- Editorial Process

- Research and Publication Ethics

- Article Processing Charges

- Testimonials

- Preprints.org

- SciProfiles

- Encyclopedia

Article Menu

- Subscribe SciFeed

- Recommended Articles

- Google Scholar

- on Google Scholar

- Table of Contents

Find support for a specific problem in the support section of our website.

Please let us know what you think of our products and services.

Visit our dedicated information section to learn more about MDPI.

JSmol Viewer

Review of energy storage capacitor technology.

1. Introduction

2. dielectric capacitor, 2.1. film capacitor, 2.2. electrolytic capacitor, 2.2.1. aluminum electrolytic capacitors, 2.2.2. tantalum electrolytic capacitor, 2.3. ceramic capacitors, 2.3.1. ceramic disc capacitors, 2.3.2. multilayer ceramic capacitor, 2.3.3. others, 3. electrochemical capacitor, 3.1. electrochemical double-layer capacitors, 3.2. pseudocapacitors, 3.2.1. redox pseudocapacitance, 3.2.2. underpotential deposition pseudocapacitance, 3.2.3. intercalation pseudocapacitance.

Click here to enlarge figure

3.3. Hybrid Capacitors

Author contributions, data availability statement, acknowledgments, conflicts of interest.

- Adediji, Y.B.; Adeyinka, A.M.; Yahya, D.I.; Mbelu, O.V. A review of energy storage applications of lead-free BaTiO 3 -based dielectric ceramic capacitors. Energy Ecol. Environ. 2023 , 8 , 401–419. [ Google Scholar ] [ CrossRef ]

- Li, C.; Zhang, X.; Wang, K.; Su, F.Y.; Chen, C.M.; Liu, F.Y.; Wu, Z.S.; Ma, Y.W. Recent advances in carbon nanostructures prepared from carbon dioxide for high-performance supercapacitors. J. Energy Chem. 2021 , 54 , 352–367. [ Google Scholar ] [ CrossRef ]

- Agajie, T.F.; Ali, A.; Fopah-Lele, A.; Amoussou, I.; Khan, B.; Velasco, C.L.R.; Tanyi, E. A Comprehensive Review on Techno-Economic Analysis and Optimal Sizing of Hybrid Renewable Energy Sources with Energy Storage Systems. Energies 2023 , 16 , 642. [ Google Scholar ] [ CrossRef ]

- Deka, B.; Cho, K.-H. BiFeO 3 -Based Relaxor Ferroelectrics for Energy Storage: Progress and Prospects. Materials 2021 , 14 , 7188. [ Google Scholar ] [ CrossRef ]

- Sayed, E.T.; Olabi, A.G.; Alami, A.H.; Radwan, A.; Mdallal, A.; Rezk, A.; Abdelkareem, M.A. Renewable Energy and Energy Storage Systems. Energies 2023 , 16 , 1415. [ Google Scholar ] [ CrossRef ]

- Xu, Y.; Wang, K.; Zhang, X.; Ma, Y.; Peng, Q.; Gong, Y.; Yi, S.; Guo, H.; Zhang, X.; Sun, X. Improved Li-Ion Conduction and (Electro) Chemical Stability at Garnet-Polymer Interface through Metal-Nitrogen Bonding. Adv. Energy Mater. 2023 , 13 , 2204377. [ Google Scholar ] [ CrossRef ]

- Yang, L.; Kong, X.; Li, F.; Hao, H.; Cheng, Z.; Liu, H.; Li, J.-F.; Zhang, S. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 2019 , 102 , 72–108. [ Google Scholar ] [ CrossRef ]