Business Ideas

Investment Ideas

Make Money at Home

- Bitcoin and Xcoins

- Earn On Social Networking

- Freelancing

- Make a Website

- Money Making Apps

- Affiliate Marketing

- Online Surveys

- Start a Blog

- Web Hosting

Startup Ideas

- Your Passion Your Money

Make Money Online

Canola Oil Project Report – Business Plan

Table of contents, market potential of canola oil manufacturing business, business plan for starting canola oil manufacturing business, implementation schedule of canola oil manufacturing business, list of approvals required to start canola oil manufacturing business, list of machinery required for starting canola oil manufacturing business, the manufacturing process of canola oil, establishment of canola oil manufacturing plant/unit, canola oil project report/ economics of canola oil manufacturing business in india, benefits of setting up canola oil production business.

Introduction to Canola Oil Project Report, Manufacturing Business Plan : Canola oil is not only one of the harmless forms of plant-derived oils on the globe but is also one of the oldest forms of fuel agents used by people. The legacy of canola oil is from around 4,000 years when the first known cases of rapeseed use were evolved in India. The cultures of Japan and China were also adopted in the beginning years around 2,000 years ago before the oil became famous in Northern Europe during the 13th century. Canola plays an important role in saving the lives of billions of people as it reduces the LDL content in the body.

Canola Oil is an edible vegetable oil that is extracted from a variety of rapeseed. It has a low percentage of erucic acid compared to colza oil. Canola Oil also has industrial uses and based on the requirement and demand both edible and industrial forms are produced. There is a huge number of cultivars of both industrial and edible forms of Canola Oil.

Uses and applications of Canola Oil : The use of Canola Oil for cooking has increased because of its health benefits. It is mostly used in the preparation of various food items like

- Coffee whiteners,

- Salad dressings,

- Cake mixes,

- Salad dressings,

- Shortening,

- Cooking sprays,

- Bread making,

- Buns preparation,

- Fried snacks, etc.

Apart from the food industry it also has a huge number of industrial uses. It is used in the areas of biofuels and oleochemicals. In biofuels, it is used in the preparation of biodiesel, bioplastics, etc. Canola Oil has high energy content and remains in a liquid state even at low temperatures and hence it is mostly preferred as biodiesel.

A Guide to Canola Oil Project Report, Manufacturing Business Plan

Health benefits of Canola Oil : Most people in the world prefer Canola Oil in their regular diet because of its health benefits. The fatty acid content has low 7% saturated fat and more amount of monounsaturated fatty acids with the highest percentage of omega-3 and omega-6 fatty acids. This lowers the cholesterol level in the human body. Hence, most of them prefer Canola Oil in all cuisines. It is also rich in antioxidants such as Vitamin E, which protects the body from the harmful effect of free radicals. Considering all these benefits Canola Oil has become the third-largest consumable vegetable oil after soybean and palm.

Canola Oil market demand is increasing day by day because of its enormous health benefits and industrial uses. The market potential of Canola Oil is expected at 31.8 million USD in 2021. It is also estimated that it might reach 44.5 million USD by the end of the year. Canola Oil market has an enormous growth rate CAGR of 8% throughout 2022-2028. This huge increase in demand is because of the highly nutritious content in it. It has a different composition of fatty acids compared to other oils. This increases the demand for Canola Oil in the coming years.

To start the profitable Canola Manufacturing Business, you need to craft a perfect business plan to make it a successful one.

- Implementation schedule

- List of approvals required

- List of machinery required

- Manufacturing process

- Project economics

- Benefits of starting Canola Oil Manufacturing Unit

- Market analysis and information on the scope of business, product demand, power provision, water facility and necessary raw materials, etc. 0-1st month

- Preparation of business plan 1st – 2nd month

- Financial support or investment 2nd– 4th month

- Selection of location and development of unit 3rd– 4th month

- Power and water connection facility

- Building construction and shed development 4th– 6th month

- Machinery and equipment purchase 4th– 6th month

- Obtain raw materials and recruitment of manpower 7th– 8th month

- Trial operations 9th month

While setting up your, your primary step should be the registration of your firm with ROC. This registration could be done based on the capital, size, and management pattern of your business. You can opt for a partnership or a proprietorship company.

A trade license must be acquired from the Local Municipal Authority and Udyog Aadhaar Registration is available on the portal of MSME. You must also get a commercial power connection for your unit.

- Registration of firm

- GST registration

- Shop Act License

- FSSAI License

- Export License

- Fire and Safety

- No Objection Certificate from pollution board

- Trade license from local municipal authority

To start Canola Oil Manufacturing Business, you need the following basic machinery:

- Seed cleaner,

- Seed cooker,

- Filter press,

- Steam boiler,

- Screw conveyor and

- Bucket elevator

In case if you miss this: Palm Oil Manufacturing Project Report .

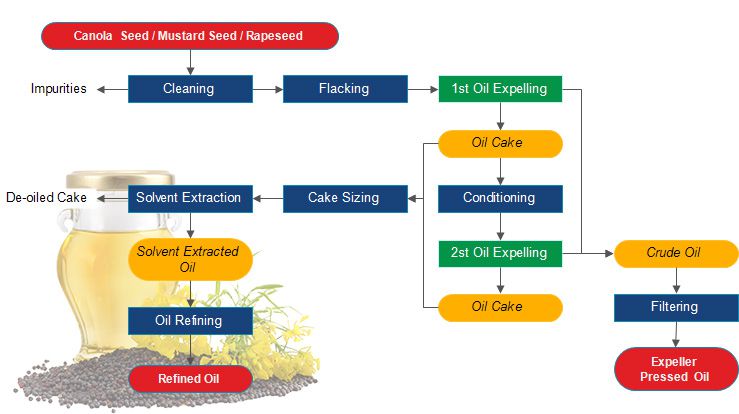

The manufacturing process of Canola Oil is simple and similar to other edible oils. In this process, the Canola Oilseeds are collected and converted into oil and meal cake. Seeds are collected, processed, and pressed to collect the oil and oil cake separately. The next step is refining and processing into finished goods which are ready for marketing.

Canola seeds are collected from the Canola plant farms. These belong to the Brassica family ( Brassica napus, Brassica rapa, or Brassica juncea ). The oil extracted from these families contains a mixture of 2-hydroxy-3 butenyl glucosinolate, 4-pentenyl glucosinolate, 3-butenyl glucosinolate, and 2-hydroxy- 4-pentenyl glucosinolate per gram of air-dry, oil-free solid.

Below are the steps involved in manufacturing of Canola Oil-

Step 1: Seed cleaning

The collected Canola seeds are cleaned and separated to remove impurities like stems, leaves, dust, metal, etc. This cleaning process improves the quality of the oil and oil loss, increases the oil yield and the quality of meal cake. If the seed cleaning is not done properly then it causes equipment friction and leads to unsafe operations.

Step 2: Seed cooking

The seed cooking process is an important step in the extraction of Canola Oil. It helps to-

- Level the moisture content to an optimum in the meal cake.

- It ruptures the cell wall which helps in the easy extraction of oil.

- Reduces the viscosity of the oil.

- Coagulates the protein content in the seed cake which helps to separate the oil.

Step 3: Canola seed pressing/ Canola Oil pressing

There are two methods in Canola Oil pressing. These include Solvent extraction and Mechanical Press. In the Mechanical press method, the cooked Canola Oilseeds are pressed by using Screw Press or expellers. This process has high value as it doesn’t involve any chemicals to process. The oil cake contains 5-7% of oil. This can be subjected to the solvent extraction method for further extraction of oil.

Step 4: Solvent extraction

Recently, the solvent extraction method has gained popularity because of its high yield. This rapidly developed solvent extraction method has a separate unit in which the seeds are first subjected to pre-pressing and later it is followed by cleaning, flaking, steam cooking or conditioning, pressing. This pre-pressed meal cake contains about 16-19% of oil and is then processed by the solvent extraction method to bring down the percentage of oil content from 19% to less than 1.5%.

This kind of combined yield of the pre-pressing and solvent extraction process gives the highest percentage of oil than the mechanical extraction method. But the oil produced by the pre-pressing and solvent extraction method contains few chemicals like isothiocyanate, peroxides, colloids, etc. which affects the taste and quality of the oil.

Hence, it is better to opt for high pressures and steam cooking temperatures to improve the oil yield in the Screw pressing method. The recent launch of the GOYUM screw press has advanced technology for processing Canola seeds to extract good quality Canola Oil.

Step 5: Canola Oil filtration

The Canola Oil extracted from the Screw press method contains some suspended solids which have to be removed to get the pure product. Hence, the oil is transferred to the screening tank or filtration tank for preliminary separation of suspended particles. This pre-cleaned oil is then transferred to a vertical pressure leaf filter for the final filtration of Canola Oil. This oil will be free from all the suspended particles and hence it can be sent for the further refining process.

Step 6: Canola Oil refining process

The crude Canola Oil contains few substances like sterols, waxes, water, phospholipids, aromatic compounds, oxidation products, free fatty acids, pigments, etc. This will affect the quality and the duration of the product. Hence, there has to be removed from the oil to get a purified one with desired quality. The crude oil is sent for refining process which involves-

- Neutralization and water washing,

- Winterization,

- Deodorization

These processes will make the Canola Oil fit for consumption.

You may also check this: Mustard Oil Manufacturing Project Report .

Land and Building: Rs. 5,50,000

Plant and Machinery: Rs. 2,70,000

Miscellaneous Assets: Rs. 55,000

P&P Expenses: Rs. 40,000

Contingencies @ 10% on Land and Building and Plant and Machinery: Rs. 80,000

Working Capital Margin: Rs. 1,35,000

Total: Rs. 11,30,000.

Means of finance :

Promoters’ Contribution @ 25 %: Rs. 2,80,000

Loan from Bank/FI: Rs. 8,50,000

Total: Rs. 11,30,000

Debt Equity Ratio: 1.96 : 1

Promoters’ Contribution: 25%.

Working capital calculation :

Raw materials/ Packing materials: Rs. 1,70,000

Working expenses: Rs. 1,00,000

Finished goods: Rs. 1,00,000

Receivable: Rs. 80,000

Total: Rs. 4,50,000

Cost of Machinery

Table Ghani 1: Rs. 70,000

Oil Expellers 2: Rs. 80,000

Filter Press 1: Rs. 60,000

Other Support Equipments, electric motor and testing facilities: Rs. 60,000

Total: Rs. 2,70,000.

Profit in Canola oil making business in India :

Sales price of Canola Oil: Rs. 32,16,000

Sales price of De-oiled Cake: Rs. 4,44,000

Total: Rs. 36,60,000

Profits in Canola oil making business = Sales – Project cost = Rs. 32,60,000 – Rs. 28,80,000

= Rs. 7,80,000.

There is an old belief that huge capital is required to begin an oil plant. But it’s not true for small-scale oil extraction units. You can start this business as a two-room building having moderate investment. The business does not require expensive machinery as well and you can install them in a small place. A small oil plant is an excellent opportunity for budding businessmen.

Financial independence is the main reason plan to work in the oil processing business. Everyone seeks financial freedom. This is accompanied by abundant returns, old age safety, and the capacity to purchase whatever you desire.

Handicraft Making at Home: A Small Profitable Business Idea

Pet-tech startups: innovations for animal lovers, tech repair services: meeting the demand for gadget maintenance, maximizing rewards: smart credit card habits for cashback and points, ultimate guide to making money from goat milk business, how to start an agricultural value added product business.

- Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with Greenhouse Farming

How to Make Profits with Organic Country Chicken: Best Strategies for Beginners

10 value-added business ideas for millets: low-investment and highly profitable, why cleaning service business becoming more profitable in metro cities in india, 10 best businesses to start in ayodhya for profits, top drone business ideas in india: unlocking aerial innovation & opportunities, top 10 service businesses you can start with no money, ultimate guide to starting a home-based advertising agency business.

- Starting a Nail Salon Near Your Location: Check List, Business Plan, Licensing, and Opening Instructions

Construction Company Name Ideas: Guide to Create New Construction Company Names

8 best small businesses to start in hyderabad: low-cost and profitable, 10 best small businesses to start in massachusetts: low-cost and profitable, 10 best small businesses to start in maryland: low-investment and profitable, 10 best small businesses to start in delaware: low-investment and profitable.

- 10 Best Small Businesses to Start in Connecticut: Low-Investment and Profitable

- Top 10 Best Online Pet Business Ideas: Exploring Cats to Dogs

- 10 Best Small Businesses to Start in Colorado: Low-Investment and Profitable

- Top 10 Profitable Small Business Ideas in California: Low-Investment Tips

LEAVE A REPLY Cancel reply

Save my name and email in this browser for the next time I comment.

Value-Added Business Ideas for Greenhouse: The Best Ways to Make Profits with...

Starting a nail salon near your location: check list, business plan, licensing,..., ideas to make money in india – a full guide, mudra yojana loan scheme, eligibility, how to apply, profit in dry fruit business (cost to start), how to make money from rice mill business in india, profitable agriculture business ideas in india, government loans for women entrepreneurs in india.

- News and Events

- Worldwide Installations

- Company Brochure

Call Now +91 99157 43183

Write to us [email protected]

- Company Profile

- About Founder

- About Chairman

- Chairman’s Message

- Production Head

- Executive Director

- Vision & Mission

- CSR & Child Labour

- Our Presence

- Certifications & Memberships

- Awards & Achievements

- Testimonials

- Fabrication Shop

- Machine Shop

- Assembly Shop

- Packaging and despatch

- Oil Expeller / Oil Press – G 10

- Oil Expeller / Oil Press – G 20

- Oil Expeller / Oil Press – G VC-I

- Oil Expeller / Oil Press – G 60

- Oil Expeller / Oil Press – G MK-III

- Oil Expeller / Oil Press – G 150

- Oil Expeller / Oil Press – G MK-IV

- Oil Expeller / Oil Press – G MK-V-C

- Oil Expeller / Oil Press – G 240

- Oil Expeller / Oil Press – G 600

- Oil Expeller / Oil Press – G 1500

- Oil Expeller / Oil Press – G 2400

- Oil Expeller / Oil Press – Palm Kernel

- Soybean Extruder

- Seed Decorticator

- Seed Cleaner

- Hammer Mill

- Copra Cutter

- Seed / Nut Cracker

- Copra Dryer

- Filter Press with Pump

- Pressure Leaf Filter

- Polishing Filters

- Vibro Separator

- Boiler – Horizontal (IBR)

- Boiler – Vertical (Non IBR)

- Thermic Fluid Heater

- Water Softening Plant

- Solvent Extraction Plant

- Edible Oil Refinery Plant

- Fish, Poultry & Animal Feed Mill Plant

- EFB, MSW, Plastic & Industrial Shredder

- Material Handling Equipments

- Palm Kernel & other Oil Expeller / Oil Press Spare Parts

- Enquire Now

- News & Events

8 Steps To Start a Small Edible Oil Manufacturing Business

- Solvent Extraction Plants

- Oil Extraction Machine / Oil Press

- Oil Mill Plants

- Cooking Oil Refinery Plants

- Baobab Seed Oil Mill Plant

- Sunflower Oil : Everything we need to know

- Shea Butter: Origins, Production, Uses and Benefits

- Canola Oil Extraction Machines

- Coconut Oil Machine

- Oil Expeller – Goyum 10

- Oil Expeller – Goyum 20

- Oil Expeller – Goyum VC-I

- Oil Expeller – Goyum 60

- Oil Expeller – Goyum MK-III

- Oil Expeller – Goyum 150

- Oil Expeller – Goyum MK-IV

- Oil Expeller – Goyum MK-V-C

- Oil Expeller – Goyum 240

- Oil Expeller – Goyum 600

- Oil Expeller – Goyum 1500

- Oil Expeller – Goyum 2400

- Oil Expeller – Palm Kernel

- Decorticator

- Seed Cracker

- Filterpress with Pump

- Boiler – Vertical (Non IBR)

- Palm Kernel & Other Oil Expeller Spare Parts

Vegetable edible oil refers to oil obtained from oilseeds and nuts through an extraction process. Since their is an improvement in people’s living standards, the consumption of edible oils is also increasing day by day. Therefore, the extraction of vegetable oil is a profitable venture that in most cases rewards manufacturers with good profitable returns.

Vegetable oil is extracted from various oil seeds & nuts such as mustard / canola / rapeseed, copra / coconut, soya bean / soybean, peanut / groundnut, sunflower, cottonseed, sesame, neem, palm fruit & palm kernel, niger, sheanuts, flaxseed / linseed, etc through a mechanical pressing process. Non-edible oil is extracted from jatrpoha seed, castor seed, etc. People use cooking oils for various purposes including Cooking / Household, Animal feed, Furniture polish and conditioner, Leather preservative / Soap making, Hair moisturizer, etc. Nowadays, vegetable oil is also used as biodiesel fuel.

So if you want to start a small business or self-employment business, a cooking oil production business may be the best option to consider.

The following steps you need to set up an edible oil manufacturing business:

Step 1. learn more about the business.

Learn more about the business is the first step to start an oil mill company. Study the requirements of cooking oil manufacturing business in terms of technology, capital, market and competition. Please visit the website page https://www.oilexpeller.com/various-activity-of-oil-mill/ to gain more knowledge of the edible oil manufacturing industry.

Step 2. Craft your business plan

Either you should have an oil mill project report or adequate knowledge to start an edible oil production plant which includes the proposed land for oil production plant, sources of funds / capital, right oil mill machinery & equipment provider , return on investment (ROI), etc.

Before choosing a place for your edible oil processing plant, you have to consider the availability of raw materials, workforce, transport & road infrastructure, electricity availability, target market, etc. Oil Manufacturing plant location should be close to the target market and raw material sources which will reduce supply and transportation costs.

Having a good business plan is like to have a compass before going on an ocean trip. This gives you insights into everything you will need to establish and run a business successfully.

Step 3. Select your source of raw materials

You have two options to obtain the raw materials needed for the vegetable oil extraction plant. You can buy oil seeds from the supplier or have your own farm for the cultivation of oil seeds & nuts.

Step 4. Find a good plant location

The location of your business is another very important factor that can make your business more successful. It’s best to find the location which is close to your source of raw materials. For example, if you will be going into mustard oil production, you should locate your extraction plant nearby mustard oil plantation or suppliers. This will reduce transportation costs which will add to your profits.

Step 5. Get the funds

You will need money for buying land, machinery, plant construction, raw materials, working capital, etc. You will easily attract investors or get loans from banks or other lending institutions if you have a detailed oil mill project report which reflects that your business is profitable, sustainable and you have good knowledge about it.

Step 6. Choose suitable manufacturer and machines

We – GOYUM are leading manufacturer and exporter of cooking oil processing line and already have experience and expertise of more than 50 years in edible oil industry. We have exported to more than 63 Countries worldwide.

We provide a complete oil extraction plant on turnkey basis with excellent after sales support. Our advanced technology plants are reliable, robust, excellent in quality, reasonably priced, works continuously with efficiency.

Step 7. Hire employees

By using different hiring mediums, you can hire employees as per your requirements for your oil production plant.

You can also use your personal contacts to hire employees / workforce for effective running of your edible oil processing plant.

Step 8. Plan the packaging and distribution

The oil is collected in the filtered oil storage tank and then it is tested, if it’s found up to the mark and has passed all the parameters set by your country government, the oil is taken to the packing stage for packing and distribution.

When the oilseeds are pressed, we get oil & oilcake. Oil Cakes have some quantity of oil in them and they are used to make animal feeds which are normally packed in bags.

Goyum Screw Press is engaged in designing, manufacturing, exporting, installation & commissioning and after-sales support for edible & non-edible oil mill industry.

We offer oil mill machinery for various oilseeds & nuts such as oil expeller / screw oil press machines , seed cleaner, decorticator, flaker, cracker, extruder, meal cooler, hammer mill, copra dryer, palm nutcrackers, boiler, oil filtration equipment, elevator, conveyor, control panel and many more.

Need guidance to start a vegetable oil manufacturing business?

Please contact us so that our sales team will communicate with you to provide you professional guidance and quotation as per your requirements. They will also share some videos, pictures, layouts, etc. for you better understanding.

Related Posts

No related posts.

Enquiry Now

(Please fill the below form)

- Troubleshooting

One Stop Service for Canola Oil Manufacturing, from Design to Installation

Canola oil is not only one of the safest forms plant-derived oils on the planet, but is also one of the oldest forms of fuel agents used by human civilization. The legacy of canola oil dates back approximately 4,000 years, when the first known accounts of rapeseed use emerged in lndia. The cultures of China and Japan were also early adopters of rapeseed roughly 2,000 years ago before the oil began turning up in lamps in Northern Europe in the 13th century. Jump ahead 700 years, canola plays a role in the life of billions of people, increasingly as an edible oil.

If you are looking for manufacturers or suppliers of canola oil manufacturing plant, ABC machinery who can garantee Top Quality, Timely Delivery and the Lowest Price should be your first choice! Contact us to get more information about our canola oil making machines and turnkey cooking oil plant!

Setup Canola Oil Processing Plant [project report]

When you are planning to establish your own canola oil factory, view the folloing projects and take the the equipment selection and factory layout for reference. Feel free to contact for equipment price list and project cost details!

Canola Oil Manufacturing Process and Equipment

- Rapeseed Pre-treatment

The first step at the canola oil manufacturing plant is the pre-treatment of the rapeseed. The seeds initially need to be cleaned. Magnets are used to remove any metals, and impurities in the rapeseed can impede the extraction process when obtaining the canola oil, so they are screened and removed. After this step, the rapeseed heated in a cooker to precondition them for extraction. After cooking, the cells of the seed need to be crushed, so they are ruptured using mechanical rollers, squashing them into thin pieces. This process eases the extraction of the rapeseed oil. The last step in pre-treatment is heating the seeds one last time. They are then left to dry out.

- Oil Expelling / Extraction (canola oil press machine & oil extraction equipment)

The oil is extracted from the pre-processed seeds using a mechanical process known as expeller pressing. This squeezes the seeds so that the oil can be extracted. The screw presses down and uses friction to squeeze out the oil. Not all of the oil will be obtained this way, as there is only an approximately 75% yield from this process. The next step is to extract what remains from the hardened oilcake with use of a solvent. Hexane is the most common option for this in a large manufacturing plants.

Cold-pressing has become more common in the manufacturing of canola oil, which follows the same general steps outlined above but does not involve hexanes extraction.

- Canola Oil Refining Process

If it is intended to be edible oil, canola oil that has gone through either of these processes must be further refined. The process of refining is essential to ensure there is nothing left in the oil that could contaminate it, which can include substances like free fatty acids, pro-oxidants and phosphatides. This will make enhancements to the flavor, color and scent. It also stabilises, neutralizes, degums and bleaches the oil. Sometimes even further steps are desirable at manufacturing plants, including winterization (a type of fractionation), dewaxing, or changing how the oil melts. (Learn more about crude oil refinery plant cost >> )

Wth advances in technology, different treatments are now used at canola manufacturing plants to process salad oils, margarine and shortenings. Inspired by the highest standards of health and hygiene, modern day processing remove unattractive colour compounds. Edible oil manufacturers increasingly use the process of bleaching, whereby the oil is moved through a natural clay. Bleaching also provides the added benefit to consumers in the fact that it doesn't involve any harsh chemicals. More specific to edible oils and indicative of the evolution of canola oil manufacturing, the final step in oil refining any type of vegetable oil is deodorization. Newer technologies such as steam distillation also removes any compounds that could give the oil an unpleasant odour or taste.

The Market Overview of Canola Oil Production

The majority of the market for canola oil is dominated by culinary use, i.e. cooking, frying, and as a widely-used ingredient in processed food. It is also used for lubrication, in cosmetics, and other personal care products. Other byproducts may be used for additional profit in this industry. An example of this would be the production of biodiesel, a fatty acid distillate- derived fuel. With environmental concern rising, this renewable fuel is an excellent added value product from oil manufacturing, and refined canola oil plays an important role in the industry.

Additionally, thee remaining oil cake has value in the livestock industry as a source of animal feed, being the second-largest source of feed in the world. It's an excellent option for this, as the low glucosinolate count and healthy ammino acids are of great nutritional value to farm animals.

Global Canola Oil Business Insights

The global market for canola oil production soared to 31.7 million tons as of 2018. By 2024, market projections predict a further volume of 44.4 million tons, which is a 5.8% CAGR expansion in the intervening years. Regions of this market are divided into Asia-Pacific, Europe, North America and Rest of the World, with North America leading this market, where it is likely to remain. Canada was the first country to produce canola oil, and it still makes a significant contribution to market growth regionally, as well as being a main exporter. It's expected that it will remain a dominant player in the regional market. (Related Post: Equipments for setting up small scale cooking oil production line >>)

The Asia-Pacitic region has an increasing demand for canola oil because of its purported health benefits and increasing awareness of this amongst the population due to the rise of heart disease or stroke. This is the reason for the expected higher CAGR. Increased health concerns is a major driver in market increase, across all regional markets. Europe is a large user of canola oil as biodiesel and cooking, and because of this is predicted to maintain steady grown over the coming years. Rest of the World is also predicted to also have significant growth across 2023.

Canola is a Low-acid Cultivar of Rapeseed Oil

Rapeseed oil extracts were first put on the market in 1956-1957 as food products. And by the 1970s, in Canada, traditional plant breeding techniques were introduced to remove the anti-nutritional components (erucic acid and glucosinolates) from rapeseed. This innovative was essential to ensuring the safety of canola oil for human and animal consumption, impacting the life of billions in the process. The name itself is testament to this fact, combining the “Can“ (for Canada) and “ola“ (for oil low acid). (Related Equipment: Rapeseed Oil Press )

With scientific breakthroughs and investment in technology, the manufacturing of canola oil has continued to evolve in sophistication and sustainability, while remaining true to the processing principles forged in the middle part of the 20th century by planters in Canada. Read about detailed differences between mustard oil, rapeseed oil and canola oil >>

The future of canola oil manufacturing continues to move in more sustainable directions. The Canola Council of Canada (CCC) has set a new target of 26 million MT bv 2025, the majority of which will come from genetic improvements and enhancements to legacy manufacturing plant production techniques. A move towards a biorefining model for canola and increased investment in processes that rely on co-streams and waste streams from processing oil and meal will become essential to achieving this achievable and sustainable goal.

- Our company is interested to build a canola crushing plant for oil extraction . our project has provided pressing 1500 Kg / Hrs initially and reach 3000 Kg / hrs the third year. I apply contacted to propose flowchart and other equipment needed for this line .

- According to your message, you alreay have the plant with 1500kg/h capacity, right? May we know what exactly the machines you have, oil press machine, oil refinery machine? For other machines needed for this line, you mean oil filling machines, bottle blowing machines, labelling machine, ink-jet printer machine? So, pls tell us what you have, then I will know what you need now.

- We are interested in setting up a canola oil production facility in USA. Please send us info on the machinery and equipment for a small economically feasible plant.

- For the canola oil extraction plant, pls tell me the capacity you need, we mean how many tons canola seeds you want to press per day? Then we can equip the suitable machines for you. Pls confirm what is your suitable 3phase voltage. Any questions pls tell us freely.

- Oilseeds Pretreatment

- Oil Extraction Plant

- Oil Refinery Plant

- Low Temperature Extraction

- Oil Filling Machines

- 100 TPD Fully Automatic Sunflower Oil Factory Setup in Kazakhstan

- Soybean Oil Extraction Plant Project Report and Business Plan

- 20TPD Coconut Oil Refining Factory in the Philippines

- 5TPD Small Scale Plant of Soyabean Oil Refinery in Ghana

- Small Scale Soybean Oil Mill Plant Exported to Ghana

Growing one of Canada’s sustainable oil supplies

Research funding

Queen’s researchers receive federal funding to address environmental sustainability in Canada’s growing canola industry.

By Caroline Alexander, Communications and Media Relations Intern

August 29, 2024

Link copied to clipboard

![canola oil business plan [Canola plant field]](https://www.queensu.ca/gazette/sites/gazettewww/files/styles/xsjpg1x3to2/public/2024-08/Untitled%20-%202024-08-29T143055.944_0.jpeg?itok=My49NhZ-)

Canola meal is a promising starting point for the development of new technologies to curb GHG production as it provides a cost-effective source of plant protein and cellulose needed for manufacturing.

Generating $30 billion per year as Canada’s highest earning crop, the canola industry, which was originally developed by Canadian farmers, is central to the financial stability of Canada’s agricultural sector. With increasing demand from both the food and the biofuel industries, canola oil production is expected to grow from its annual 20 million tons to 26 million by 2025.

However, canola oil is only half of the picture. Through its production, canola oil generates large amounts of canola meal, a low-value solid byproduct with extremely limited uses. While a small portion of this byproduct is used to supplement livestock feed, most is simply discarded, where its decomposition contributes to greenhouse gas (GHG) production.

To combat this problem, Queen’s researchers Kevin De France (Chemical Engineering) and Warren Mabee (Policy Studies) are leading an interdisciplinary project between four universities and five partner organizations to increase agricultural sustainability by repurposing canola meal. With $3.2 million in funding provided over four years by the NSERC-SSHRC Sustainable Agriculture Research Initiative in collaboration with Agriculture and Agri-Food Canada , the researchers intend to refine canola meal into a series of eco-friendly products and understand the policy and financial implications for these changes.

“As a critical aspect of Canada’s agricultural economy, canola oil demand will continue to grow, and with it, so will the environmental impact of the industry,” says De France. “In fact, canola processing capacity in Canada is set to explode within the next few years, so it’s essential that we find alternative uses for canola meal. Developing novel products and technologies to curb GHG production while also improving productivity and financial success for Canadian farmers is central for us.”

Despite its current lack of use, canola meal is a promising starting point for the development of these new technologies as it provides a cost-effective source of plant protein and cellulose. De France and colleagues plan to explore the purification of these compounds for manufacturing into four products; bioplastics including silage wraps and mulch films, delivery vehicles for chemical agents such as pesticides, biodegradable scaffolds used to produce lab-grown meat, and electrodes for carbon capture and storage.

“With an estimated 60,000 tons of plastic used each year within Canada’s agricultural sector alone, it’s clear that practical bioplastic alternatives would help reduce plastic waste and microplastic pollution. Combining this with other applications such as carbon capture would provide far reaching effects benefiting Canada’s efforts to fight climate change.”

– Dr. Kevin De France

Assistant Professor, Chemical Engineering

To address knowledge gaps regarding the application of canola-based bioproducts, the project will also focus on the development of a policy roadmap for the new Canadian canola bioeconomy. By working directly with The Canola Council of Canada who represent canola farmers, the researchers will analyze the financial impact associated with applying these new steps of canola meal recovery and processing. As well as assess the willingness for farmers to adopt these new eco-friendly technologies.

“Recent research in Canada’s bioeconomy has focused more on biofuels, but we see immense potential to create practices that repurpose a wide variety of agricultural byproducts,” says De France. “To do this we need to ensure that these practices are implemented within an environmentally and financially sustainable policy framework.”

By providing training opportunities for 40 highly qualified personnel, including undergraduate, graduate, and postdoctoral researchers, this project will foster long-lasting innovation and growth within Canada’s agricultural economy – helping advance the United Nations’ Sustainable Development Goals (SDGs) along with the Government of Canada’s goal for net-zero plastic waste by 2030.

To learn more about the NSERC funding, read the announcement .

Media Contacts

Editors' Picks

Sparking canada’s supercomputing renaissance, improving bladder cancer treatment, protein research breakthrough, related stories.

Canadian urban mobility is woefully lacking, but building a better future is still possible

Advancing mining in a high-tech world

Funding to fuel research and innovation

Queen's celebrates newest inductees to the Royal Society of Canada

IMAGES

VIDEO

COMMENTS

#CanolaOil #EdibleOils #FoodBusiness. Here’s a simple guide to help you get started: Research and Planning. Begin by researching the canola oil industry. Understand the market demand, your potential competitors, and your target audience. Create a solid business plan that outlines …

A guide to the canola oil project report, Canola oil manufacturing business plan, Canola oil extraction process, and profit in the Canola oil manufacturing business.

Quality refined canola oil production line is needed to make sure that the produced canola oil is much in purest form. Just send an inquiry and tell us your cost budgeting, capacity requirment …

A Sample Mustard Oil Production Business Plan Template. 1. Industry Overview. Mustard oil production business is a subset of the Margarine and Cooking Oil Processing industry and …

The journey of canola oil production is a testament to the meticulous care and precision involved in bringing this versatile and nutritious oil to consumers’ tables. From seed …

Start Canola Oil Making Business. The Asia-Pacitic region has an increasing demand for canola oil because of its purported health benefits and increasing awareness of this amongst the population due to the rise of heart disease or …

With increasing demand from both the food and the biofuel industries, canola oil production is expected to grow from its annual 20 million tons to 26 million by 2025.